|

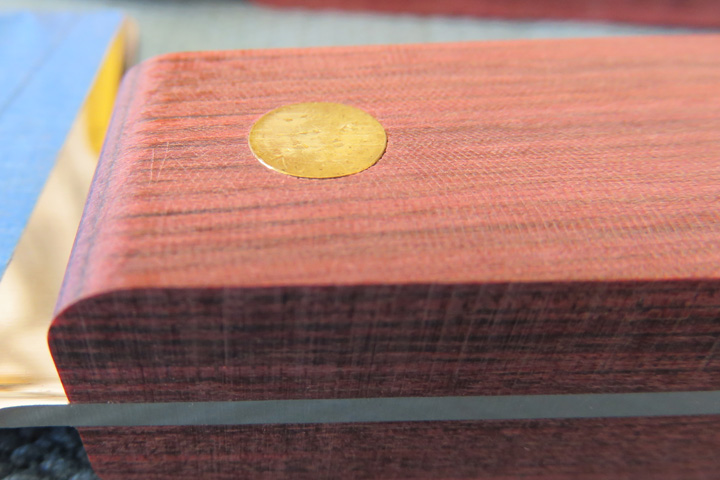

Here is what it looks like when the rivet has been

squeezed all the way. I should have done this the first time

because it was much easier like this.

Again...live and learn.

|

|

|

|

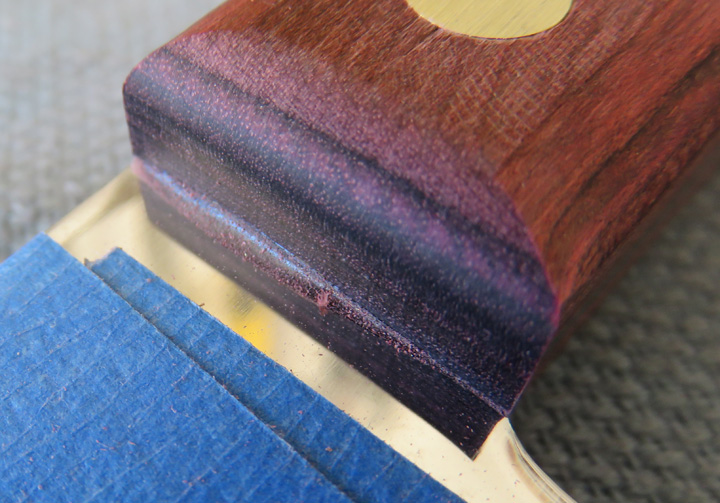

I still had a small amount of squeeze-out with the

epoxy which will need to be removed.

|

|

|

|

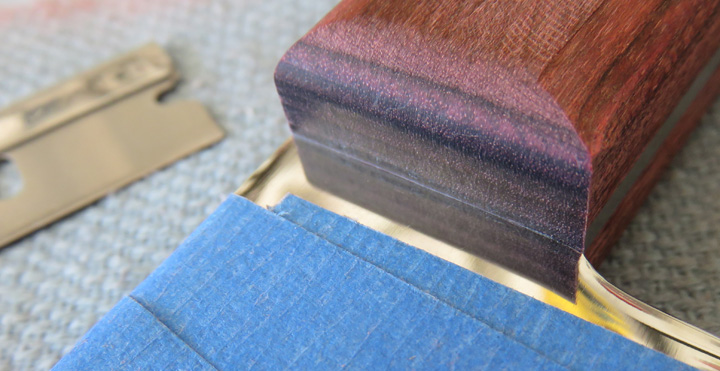

I used a razorblade for this operation which worked out

great. I worked the blade straight down towards the blade first, then

towards the handle, working a small section at a time. I then worked the

blade straight down again removing small pieces until it was gone. Now

it's time to hand sand all the sharp corners and end with 320 grit

paper.

I placed more tape around the blade and against the

handle before I started sanding. I also used a file to help form a

radius between the front and side of the handle that is right next to

the blade. The file removed material faster than using sandpaper only

and was easier to control. After the file I came back with paper and

blended everything.

|

|

|

|

After many hours of work, here are the finished knives.

I'm pretty happy with them so far but I may put some mineral oil on the

handles later. Speaking of the handles, I made each one a different thickness

relative to the blade size:

| Type |

Handle Thickness |

| |

|

| Paring |

.570 |

| Utility |

.600 |

| Fillet |

.625 or 5/8" |

| Sm Chef |

.650 |

| Carver |

.730 |

| Chef |

.750 or 3/4" |

|

|

|

To see what it would look like, I used a scrap piece of material,

applied some mineral oil and it looked pretty good but it did make the

color a little darker by one or two shades. No big deal because that

made it look that much richer to me. If I do use the mineral oil, I'll

talk about.

|

|

|

|

Last Piece of the Puzzle

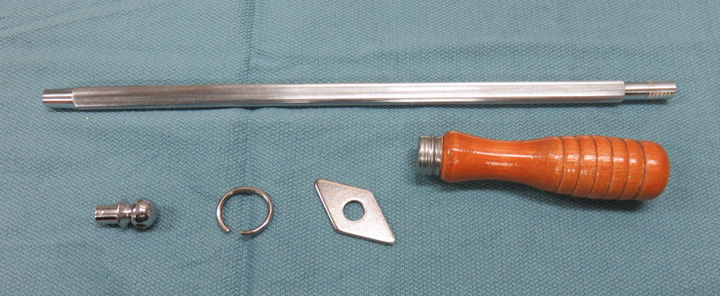

I bought this sharpening steel online thinking that it

would work for my project. Turns out it's not made very well but you get

what you pay for...right? Now a sharpening steel happens to be a big

part of this knife holder so hang in there and

you'll soon see why.

|

|

|

There are many things wrong with this piece, and the first one being the

handle. Some of the grooves are missing from one side because the handle

was off-center when the factory sanded it. Yes I could use it as is but I still have some

time before the big day so why not improve on what I have.

|

|

|

|

This sharpening steel consists of six pieces but I couldn't get the ring

off the handle without damaging it. What I plan on doing is

making a new handle but I think I'll keep the other four pieces. I'm not sure

how I'm going to make this handle yet but it looks like I'll need to use

a lathe and that means I'll need to use a machine at my work.

I know that I

said this entire project would be made at home but this was

unforeseen. On the other hand there are many choices of sharpening

steels on the market which means this step isn't a necessity. I'm making

a handle so everything matches but this project would still work and

look great without remaking the handle.

Speaking of

a lathe, I'd really like to have one of my own someday which would

complement my milling machine. Soon!!

|

|

|

Before I get started on the handle, I measured the one that came with

this sharpening steel along with my

daughters as well. I really like the design of Tracey's so I

think I'll try making one like hers. Either way I'll need to glue three

pieces together to make one so I cut these from one of the blocks I had

leftover and milled the sides and tops like I did the knife handles. Now it's time to use more epoxy.

|

|

|

|

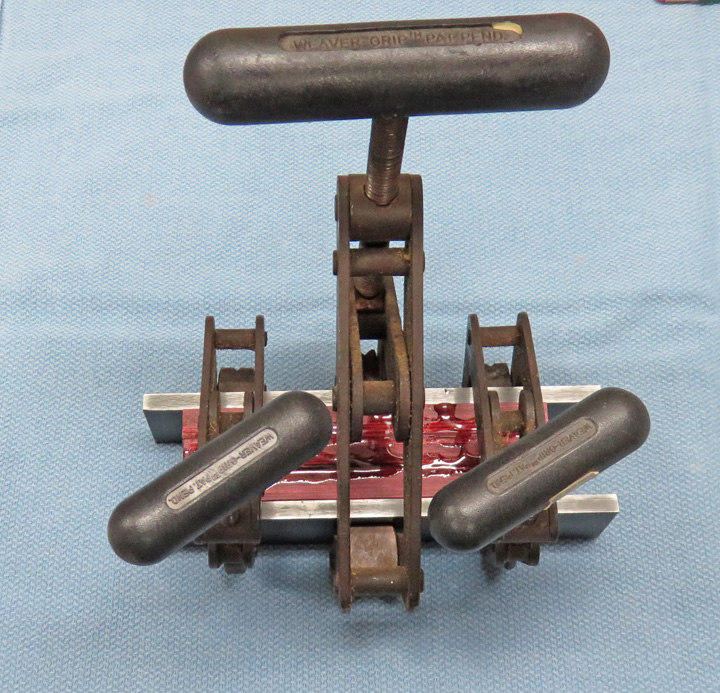

I've found out over the years that it's very important to

distribute the camping force evenly and to do this I'm using some 1/4"

machinist parallels. These are made out of steel, however, you could use wood

or aluminum

just as well. I have many

different sizes of parallels so it just seemed natural. In other

words, whatever works for you.

|

|

|

|

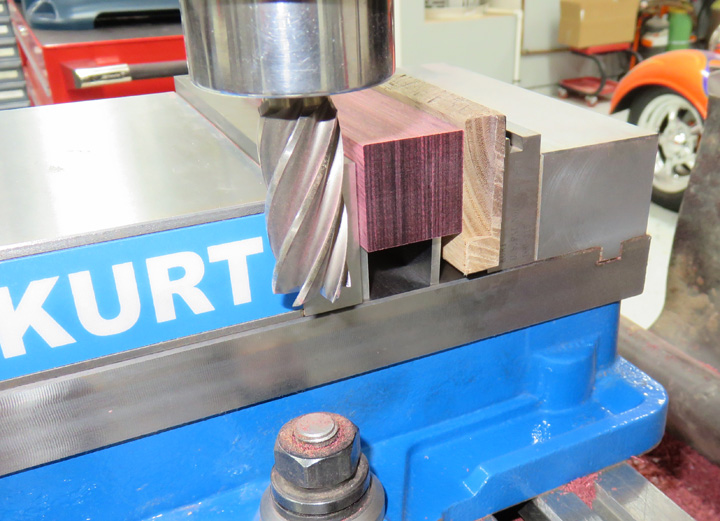

I cleaned up the block on all six sides making sure it

was

square and parallel. Here I'm cleaning up the ends and note the scrap

piece of wood against the solid jaw. Again this helps prevent chipping

the end of your work piece because even though this material is man

made, it still has a grain to it like wood has.

|

|

|

1

2

3

4

5

6

7

8

9

10

11

12

13

14 |