|

More Machining

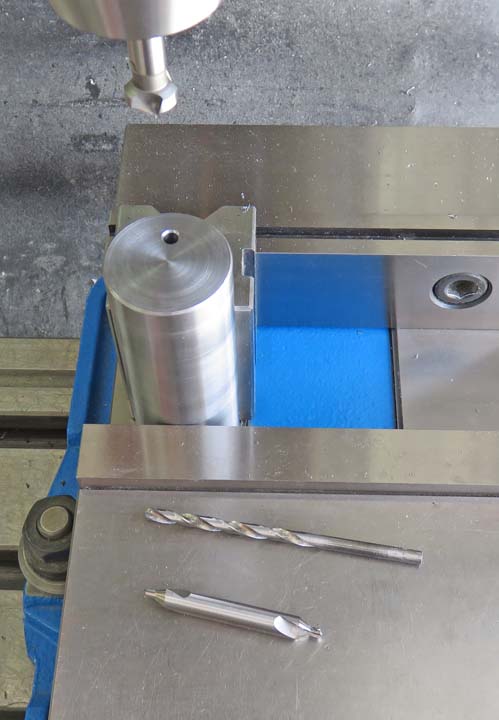

This is a clearance hole for the 1/4" screw to pass through.

|

|

|

|

This should give you a better idea of what

I'm doing. The 1/4" hole is positioned so I have a small amount of

clearance between the two larger tubes. This way the outer tube on the

upper section can spin. Notice the large chamfer on the lower tube, this

is for a flat head screw.

|

|

|

This is the opposite end of the chamfered hole. I drilled and tapped

1/4-20 threads on this side.

|

|

|

Here are some of the stainless hardware that I'll be using. And after

making all of the parts that I'll need, another trip to the hardware

store will be needed for some more stainless fasteners.

|

|

|

|

This piece looks similar to the aluminum spacer that I

made earlier. However, this piece is made out of steel

and will be getting welded to another piece that goes to the flagpole

base. As you can see by my scale, I've bored it 3 1/2" deep. The

opposite end is 1/2" thick so I can weld without worrying about burning

through.

|

|

|

Here is the opposite end from the part above. I'm drilling a drain hole

water can run out.

|

|

|

Actually, the hole on the bottom will get welded over so I drilled a

cross-hole that will be pointed towards the ground. Just looking ahead

here.

|

|

|

|

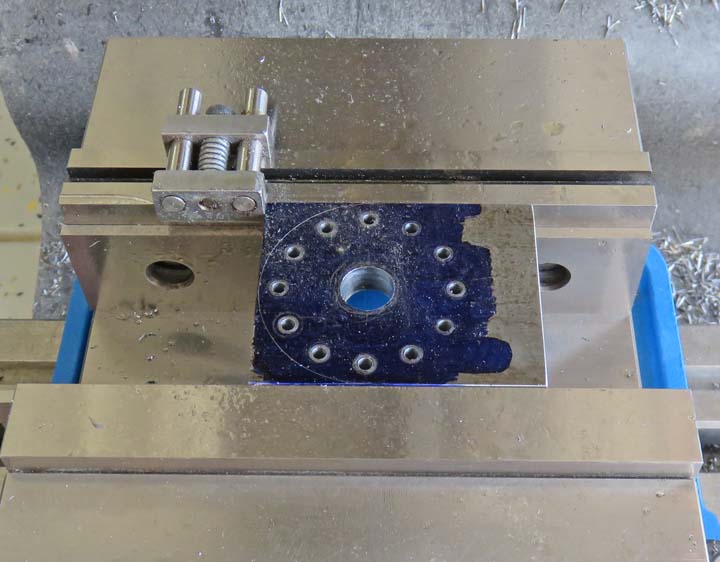

This piece will get welded to the round part above. The

holes are 1/8" diameter and will have pins in them when I'm finished.

The pins are so I can 'clock' the flagpole at the angle of my choice.

And these pins will go into a mating part that I made a couple of years

ago that I'll show you later. The left end will have a radius (scribed

line) and the

other will be tapered to fit my piece above.

|

|

|

|

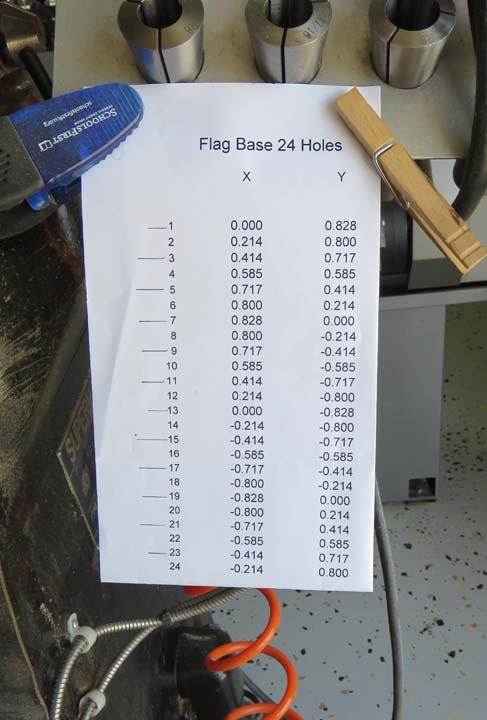

The paper that you see below has the coordinates for my

base (that I made awhile ago) that has 24 holes in it. But I only needed to use half of them for

the above part. Note the lines at every other location equaling my 12

holes. It's a good thing I saved this paper because it came in handy.

|

|

|

|

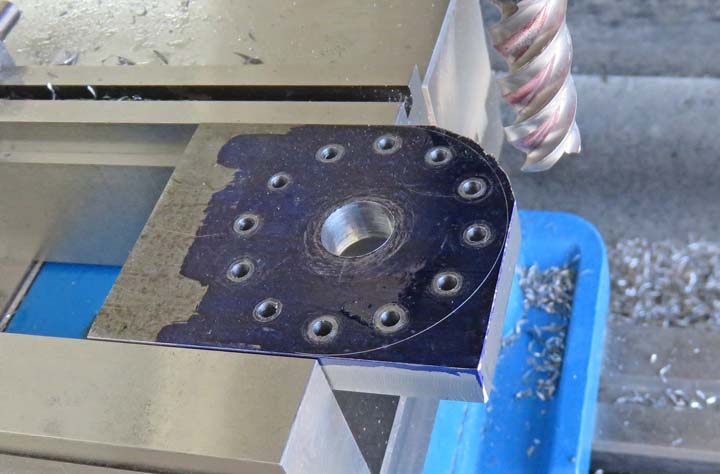

This part is made out of 3/8" thick steel. I'm

roughing away some material here to make it easier to sand later. All

you do is move both X and Y handles at the same time, staying away from

your line while machining.

|

|

|

|

1

2

3

4

5

6

7 |