|

Shop Aid

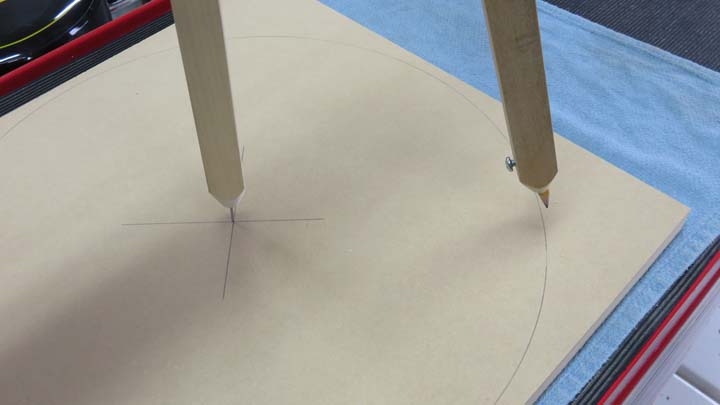

I cut my MDF oversize to 15" square, which should give me plenty to

work with. I also got tired of using that string method to make some

circles so I made a large compass.

|

|

|

|

I made the compass out of 3/4" square pine and they're

20" long. I drilled a hole for a pencil on one end and cut the head of a

finishing nail for the other. If I need to sharpen the pencil it's

easily removed with a small screw (see the above picture). They are held

together with a 1/4-20 bolt and a wing-nut, which makes it easy to

adjust and it was really easy to draw my 14" circles.

|

|

|

|

Back To Work

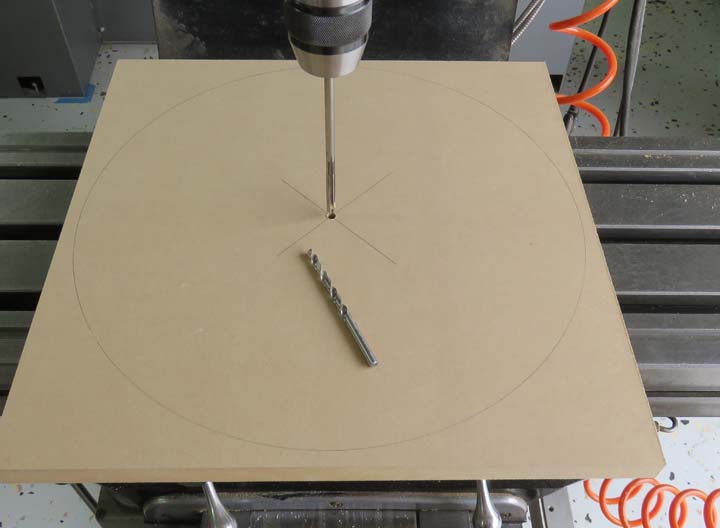

I drilled and reamed a 5/16" hole in the center because that's the

size of the clock mechanism. And I'll use this hole to center my work on

the rotary table too.

|

|

|

I roughed out the O.D. on my bandsaw which went quickly because MDF is

soft.

|

|

|

And just like that I have six pieces ready to work with.

|

|

|

|

Bullets

Now if you're wondering why I have all this ammo

reloading stuff here, well...it's because I'm going to add my own

special touch to these clocks. Now I use to reload all my ammo

awhile back, which included shotgun, rifle and pistol but I sold almost

all my equipment many years ago. However, I don't plan on reloading here

per say, but I do have a plan to remove all the powder from the bullets

that I'll be using.

What you see below is a bullet puller with two different

size collets along with two different seating dies, and two shell

holders round out what I'll be using here.

|

|

|

Here is my very old single stage reloading press made by RCBS. This type

of press works very good but it's slow. However, this is one of a few

pieces that I didn't sell, just in case I wanted to load for my deer

rifle again.

|

|

|

|

The first thing I did was remove some of the rust with

WD-40. Once all the movable parts were working freely again, I clamped

the press to my workbench with my 6" Kant Twist clamps. Yes that's the

real name of those clamps and they're not cheap, but I've owned them for

many years. Side note: this style

of clamp is unmatched in holding strength just in case you wondered. Now

I'm ready to get started on some bullets.

|

|

|

|

I'll be using 9mm for the minutes and .223 caliber for

the hours. Another side note: with all the problems in this season of

life, it's a shame to disassemble all this ammo because it's not cheap

right now. In fact, it's very hard to get either one of these calibers

just about anywhere. In fact, I'm sure I could sell them and even make

money. Anyways.....moving on....

|

|

|

|

I'll be starting on the .223 ammo and I have the bullet

puller die in the press. What you do is pull down on the large green

handle till it bottoms out, then turn a smaller lever at the top of the

die to tighten the collet onto the bullet, then push the large green

handle upwards again. At this point, the bullet is still in the collet

in the die so you remove the brass, then turn the lever on the die and

the bullet falls out. I let it land in my hand when doing this.

|

|

|

|

1

2

3

4

5

6

7 |