|

New Tools

The next day I went online and bought a new 'planer and

stand' by DeWalt. And they were delivered in one day from Home Depot,

wow!. I

should have bought one of these many years ago because it would have

saved me a ton of time over they years.

|

|

It will handle a 13" wide board and has a built-in thickness setting

that include; 1/4", 1/2", 3/4" one inch and more. This should make life

much easier for sure.

|

|

It also came with in-and-out feed tables. Now it's time to make some

sawdust!

|

|

|

I plugged in the planer and ran a board through it

without the vacuum attached. Well that was a big mistake because it

looked like it was snowing in the garage, so out came the vacuum. I used

my shooting target stand to hold the hose along with some duct tape to attach the

hose to the planer.

|

|

|

Here's a better look at my high dollar

attachment. This worked but as soon as I was finished, I bought a real

adapter.

|

|

|

|

While the wooden desktop was still on my sawhorses, I

used it as a workbench. I wanted the thickness of my box to

be 1/2" so I set the dial on my planer to that setting and started

cutting. After a few minutes, I started to get the hang of how this new

tool worked. And once I hit the 1/2" work-stop on the planer, my work

pieces measured at .503". That was impressive because I didn't expect to

have those pieces measure that close. Needless to say, I was very

pleased with the results. And what a great finish it left too. Again,

I'm really happy with this DeWalt planer.

|

|

|

Once I was finished, I checked my shop vac and it was full. Now this was

my first time using a planer and I can see that I may need a different

vacuum system in the near future.

|

|

|

|

Machining

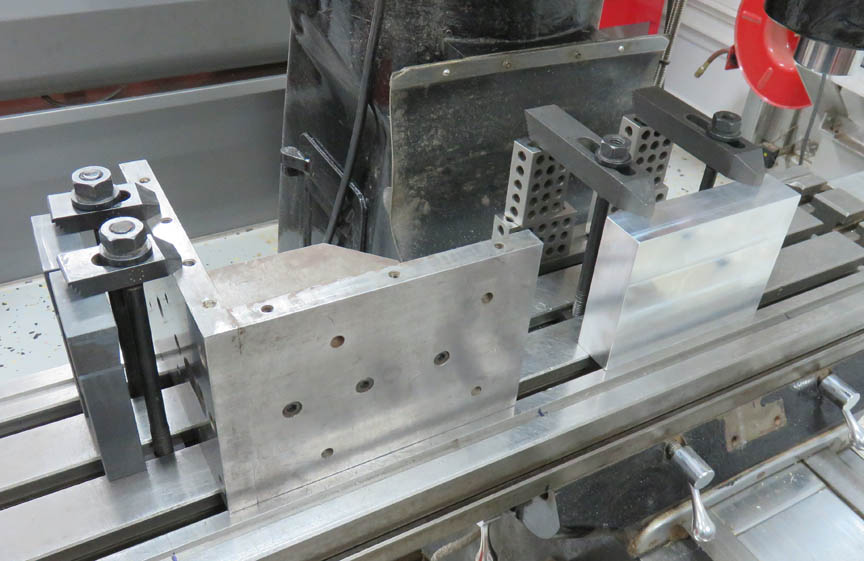

I'll be using some wood dowels to join all the pieces

together which meant I would need something to rest the work piece against.

I'm using my angle plate on one end and a machined piece of aluminum for

the other end.

|

|

|

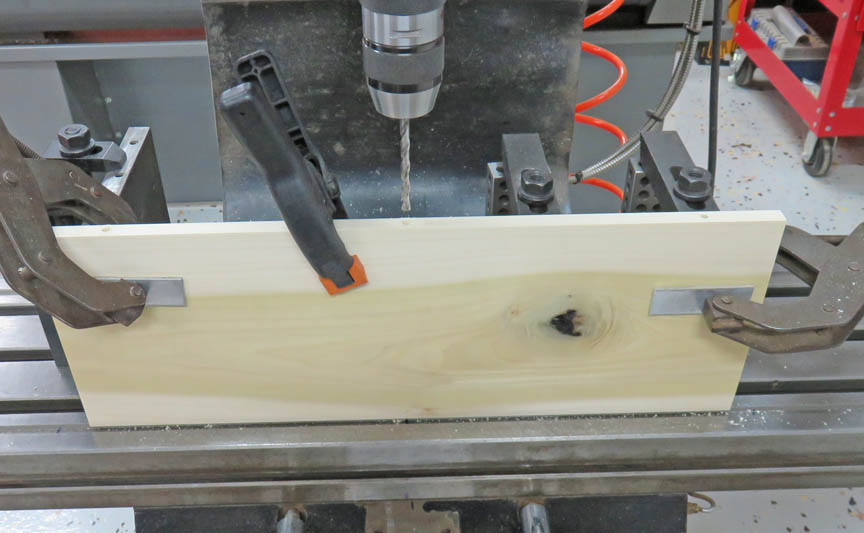

I used a few clamps to hold my work piece while I drilled and reamed

some 1/4" holes for my dowels.

|

|

|

This worked out great because I used my digital readout for the hole

location.

|

|

|

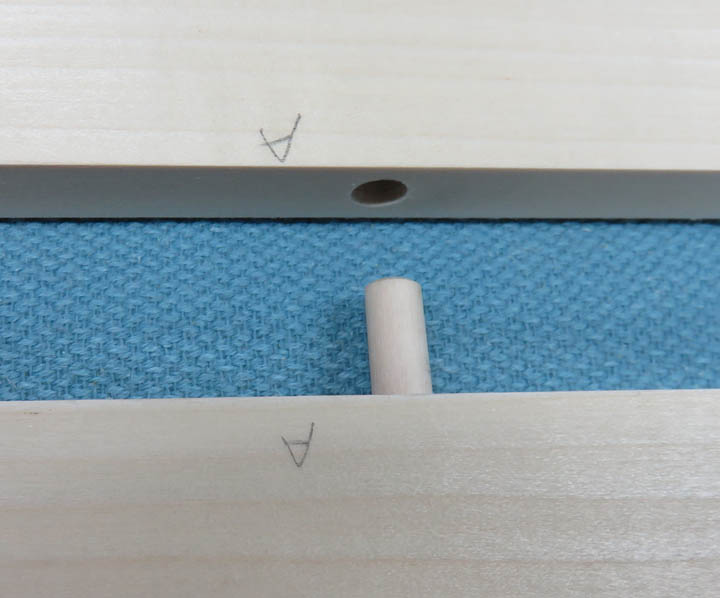

Close-up of the dowel and hole.

|

|

|

|

1

2

3

4

5

6

7

8

9 |