|

Round Blocks

I want to make a few round blocks that are 1" long X 1"

diameter. With the wooden desk measuring at one inch, this isn't enough

material for me to work with so I'm gluing some pieces together.

|

|

|

I saw cut them into two inch lengths so I

have enough to grab onto while in my lathe.

|

|

|

|

The one inch diameter is finished, along with some

sanding and now it's time to cut off the block. I'm using my parting

tool for this but I'm staying away by about 1/4" and then sand

the back edge. Once it was all sanded, I cut all the way through.

|

|

|

|

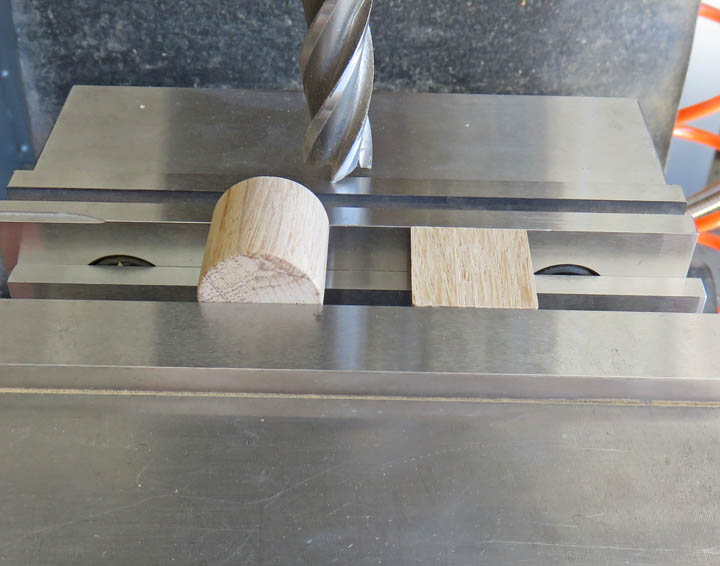

I wanted some of the round pieces to became 'half round' so I'm milling

them here.

In total, I made many different size blocks ranging from

one inch long to four inches long, some being square, some being

rectangle and like you see below, some being round. Now it's time to

make something to put them all in.

|

|

|

|

Making A Box

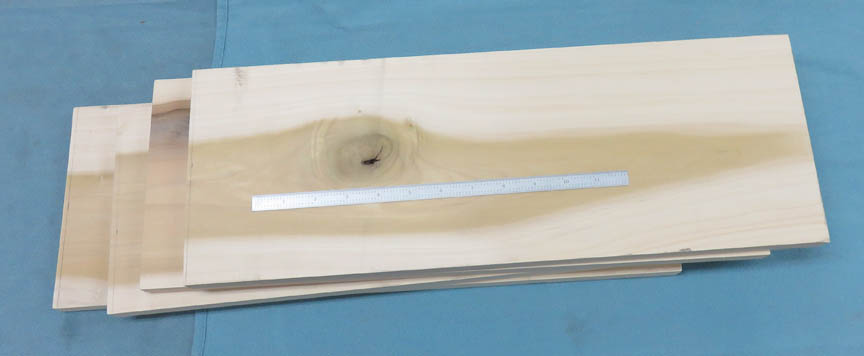

I'm making a wood box out of poplar, mostly because it's

nice and light. The reason for this is because I ended up with a lot of

blocks, so this lighter wood is a

good choice. However, poplar is not very hard but it's easy to work

with. The pieces are 21" long X 8" wide. I plan on making a box that

will be 20" X 14 1/4" X 3 1/4" tall.

|

|

|

|

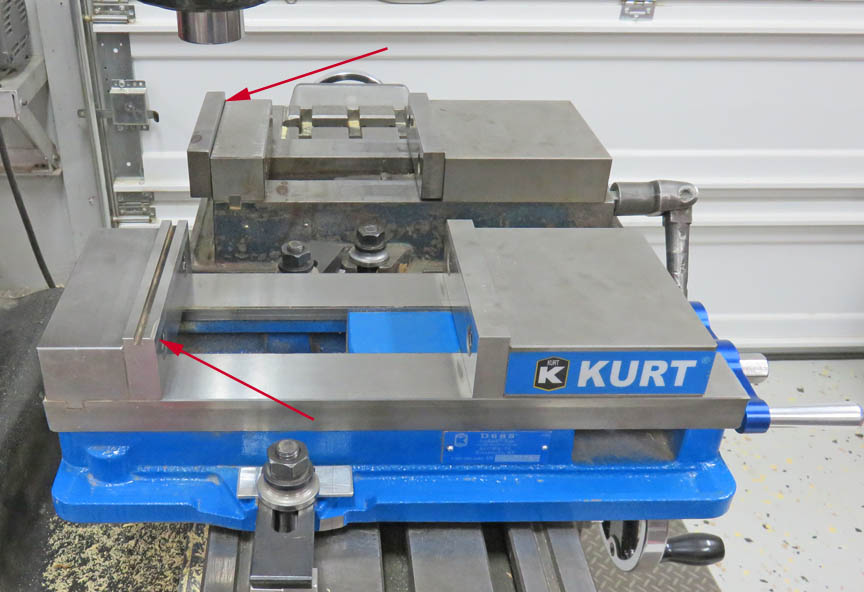

I want to machine the thickness down to 1/2" so I'll be

using two vises for this. My Kurt vise has no problem holding larger

pieces, however the other one does not. What I'm doing is moving the

hardened jaw to the other side of the solid jaw to give me more room to

hold my work piece.

Notice the two arrows are pointing at an inside jaw and

an outside jaw. But the two jaws are in alignment with each other so it

will hold my work piece parallel. Now this is an unconventional setup

here because you would normally have both jaws line up with each other

without doing what I've done. On the other hand, I say...whatever works!

|

|

|

This should give you a better idea of what I'm doing. And now I'm

ready to start cutting.

|

|

|

Here you can see I'm machining my work piece, which is a little messy.

|

|

|

|

After machining both sides I ended up with this. Look

close and you'll see the center is smaller than the outer edges, which

is not good. As I'm holding the board in the vise, it's moving upwards

while it's clamped. Once I open the vise, it relaxes and moves back.

That's why the center is smaller than the outside.

The reason this is happening is because I'm not able to

hold the piece of wood down into the vise like I need to. With the one

vise being smaller, I'm forced to hold onto a very small portion of my

work piece, bowing it while it's being clamped. Now if this were a piece

of metal, this wouldn't happen. So now what am I going to do? If I only

had a wood planer.

|

|

|

|

1

2

3

4

5

6

7

8

9 |