|

Working With Wood Continued

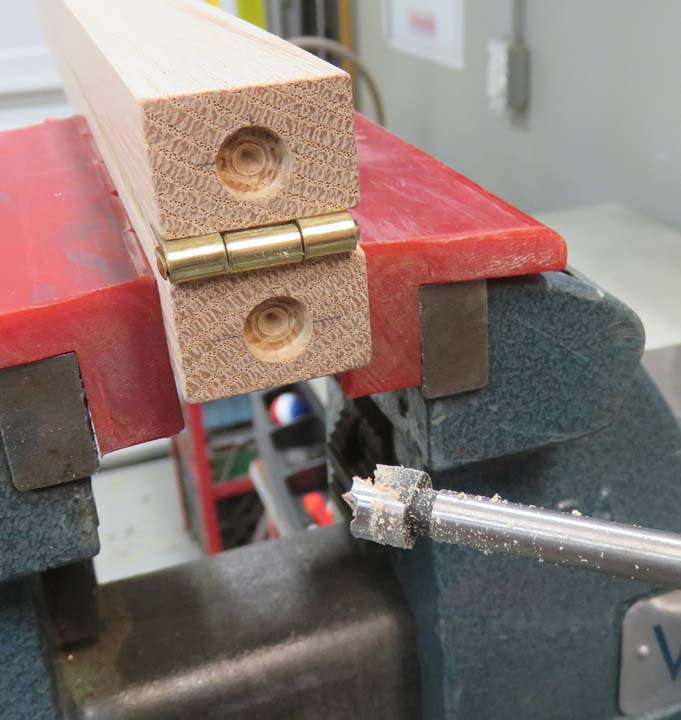

This will give you a better idea of what I was talking

about. I placed my 1 X 2 X 3 block against the end of the leg and then placed my

hinge against the block. This kept the hinge in the correct location

while I drilled my screw holes making sure they were in the right place.

Whatever works...

|

|

|

I'm making some pockets for magnets that

will help hold my legs in place when folded and extended. I used a 3/8

Forstnor bit and only went 1/8" deep.

|

|

|

|

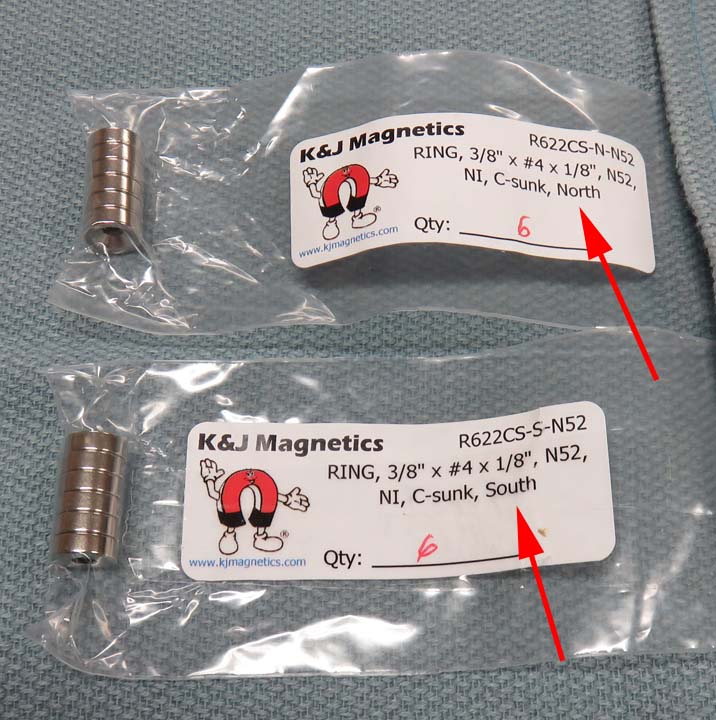

My plan is the have these magnets placed with one leg

having it's north pole sticking out, and the mating leg with it's south

pole sticking out. This way they will attract each other and want to

stick together. These magnets also have a chamfer on one side making it

easy to fasten them using a flathead screw.

|

|

|

Here is what it looks like with the magnets installed. Once the legs are

touching each other, the magnets will grab each other and will act as one

leg. In theory that is.

|

|

|

|

It's finished

Here is my out-feed table installed and tucked out of the way. I also

made sure it would clear the vacuum duct at the bottom.

|

|

|

|

Here you can see both legs folded against the table.

I also installed some magnets near the ends of the legs to keep them

locked in place while it's folded. The end of the out-feed table sits

below the work surface of my table saw and I can still used my cross-cut

sled without anything hitting it.

|

|

|

Here is one of the magnets installed on the legs that keeps it flat

against the bottom of the table.

|

|

|

And here is the one on the bottom of the table that mates with the leg.

This worked out pretty good.

|

|

This was a fun project and it works great, deploys fast and stays in

place while using it.

|

|

|

1

2

3 |