|

Working With Wood Continued

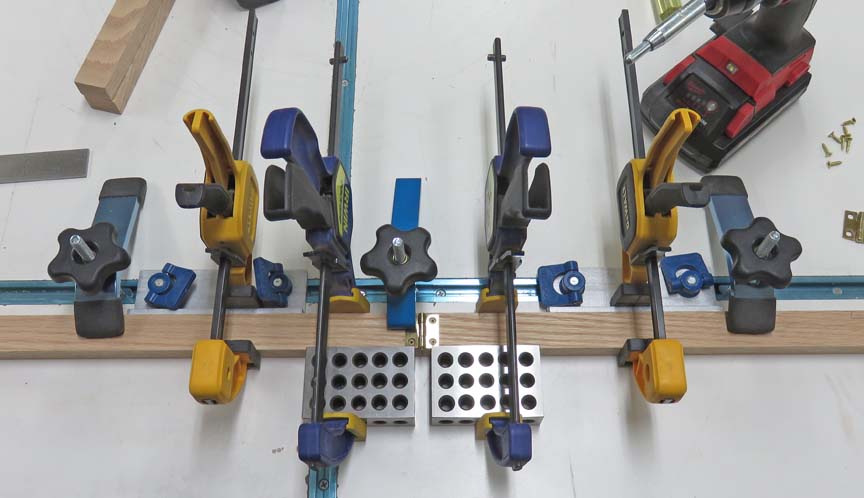

I clamped around the perimeter and then used some heaver items in the

middle.

|

|

|

While the glue was drying, I started

mounting my hinges to my wood blocks.

|

|

|

I had to add a radius to the wooden blocks so the table would fold

correctly. This only took a few minutes with a wood chisel and I didn't

even remove the blocks.

|

|

The next day I used the same 3/16" roundover bit on both top and bottom

surfaces of my folding table.

|

|

|

I made a temporary leg out of scrap material to hold up my work piece

while I attached the hinges. This worked out well and now it's time to

make some legs.

|

|

|

|

I made some legs out of oak that I had laying around which

measures 3/4" X 1 1/4". Each leg will be constructed out of two pieces

because the distance from the table to the floor is too long to be

folded up as one leg. So I decided to make these legs foldable onto them

selves. This way when they're straightened

out, they will be at the right length.

|

|

|

These small hinges will be used on the legs. One hinge will be attached

to the table and one part of the leg, and the other will allow the legs to fold against each

other.

|

|

|

|

To make sure both legs fold and lineup with each other,

I used the T track on my portable work bench along with some 6" long

work-stops that clamp into the track. Then I clamped my work pieces to

the work-stops so they would stay in alignment. With the use of some 1"

X 2" X 3" blocks, I placed my hinge against them and then clamped

everything together to keep the hinge and legs in alignment. Also note

the single clamp holding down my hinge. This made sure it didn't move

while I was drilling some pilot holes for screws.

This particular hinge will be used to fold the leg onto

it's self. This will make more sense a little later.

|

|

|

|

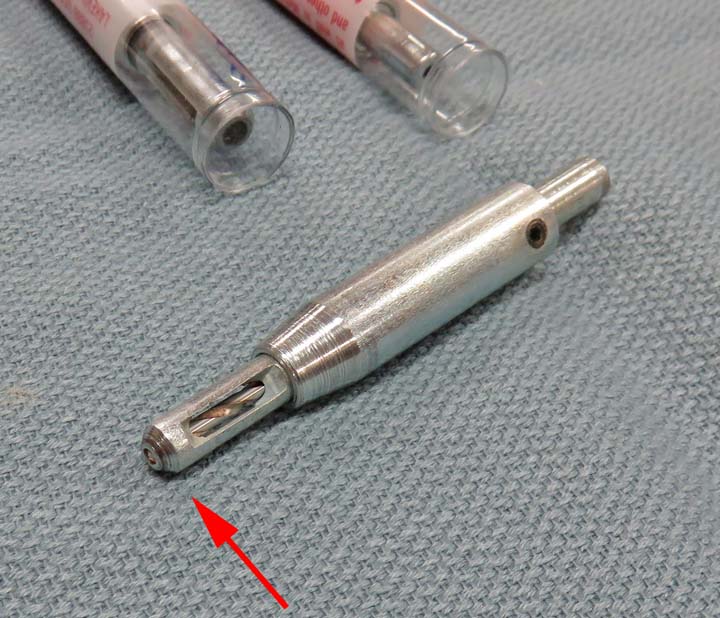

These centering drills work great for putting your pilot

hole in the exact location that you want. Notice the chamfer or angle at

the end of the centering drill. That angle locates in the holes of the

hinges to make sure the hole stays in the center.

|

|

|

|

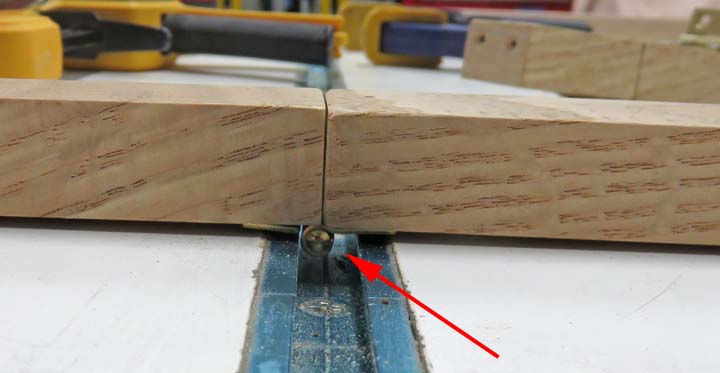

Once I had the hinge drilled and fastened on, it was

time to attach one more to the end. What you see below is my work piece

(leg)

turned upside-down with the hinge resting inside the T slot. This allowed me

to keep the wooden legs flat against the work bench making it easier to

line up my other hinge.

|

|

|

|

1

2

3 |