|

Making a Case Continued

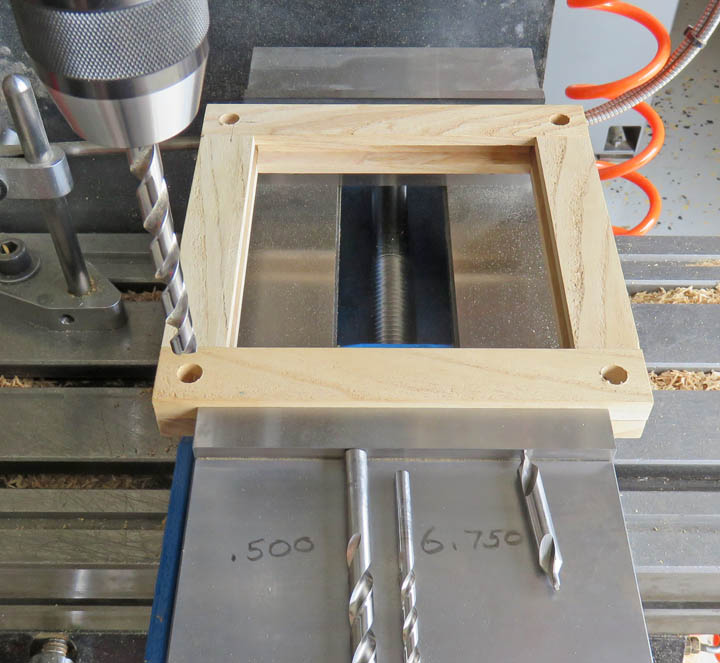

Now it's time to cut a slot for the plastic to rest

inside of.

|

|

|

|

I'm using a 5/16" diameter end mill here to produce my

slot for the plastic.

|

|

|

|

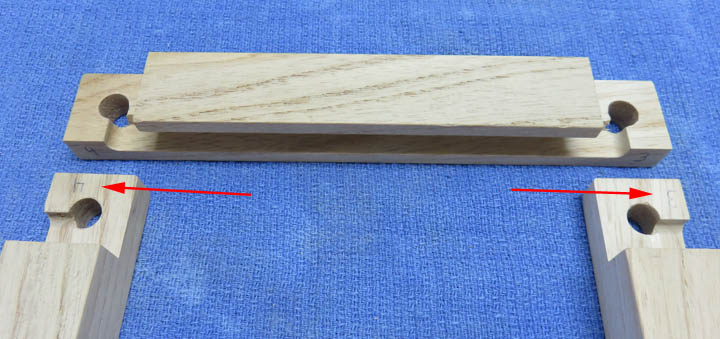

Here is what it looks like after machining. Now it's

time to join the four pieces of the frame together.

|

|

|

|

I'm stepped up from a 1/4", 3/8" to a 1/2" diameter drill to make a thru hole at

each corner. Then I'm going to make some wooden pins to press into the holes.

|

|

|

|

The pins will be made out of black walnut just like

the frame is made out of. But the material I'll be using is more of a traditional color

of said wood. These were some scraps I had laying around.

|

|

|

|

I cut each piece to roughly the same size and now it's

time to turn some pins.

|

|

|

|

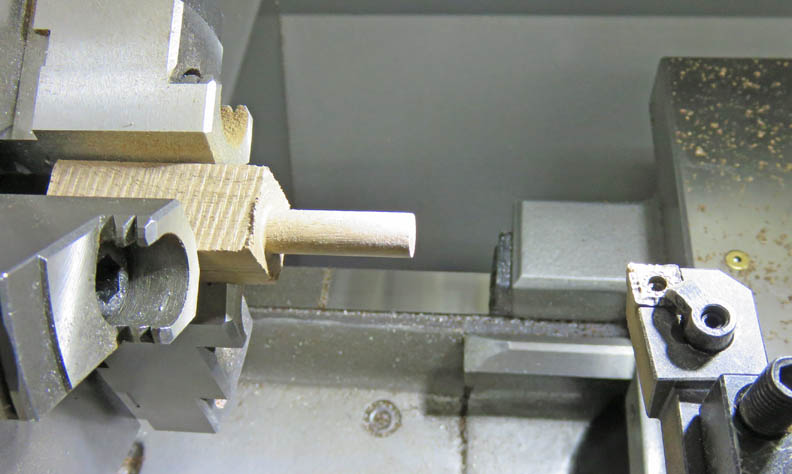

I used my lathe to turn each piece, which didn't take

long. I cut them off with a hacksaw and then machined them to length.

|

|

|

|

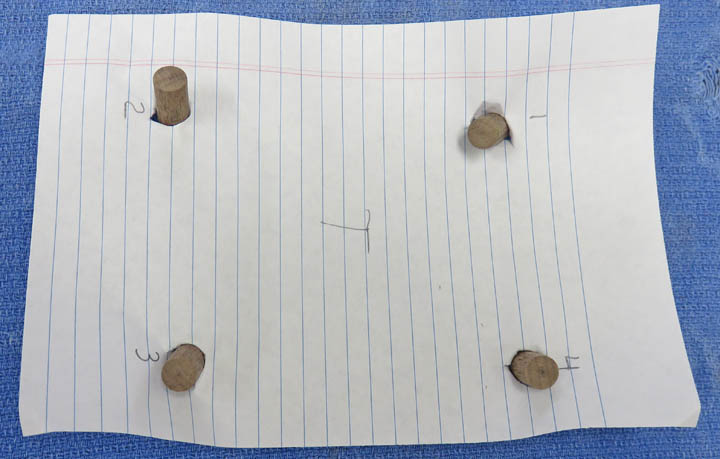

I numbered each corner (arrows) to make sure things

lined up after everything was sanded. This way I know each piece will go

back together correctly.

. |

|

|

|

I numbered each pin because some fit better than

others.

|

|

|

|

I used mineral oil on all the wooden pieces which made

them look very nice.

|

|

|

|

1

2

3

4

5 |