|

This project will be very patriotic because I'm making

some United States flags made out of wood. Speaking of wood, I'll be

using curly maple, black walnut and sapele. I've never worked with

sapele (red) but it looked better than mahogany when choosing between

them. Anyways, what you don't see in this picture is the other three

pieces that I had to buy because I ran out of all three types of wood. No big deal because

there's a

killer sandwich shop called

D'Elia's Grinders right

around the corner from Reel Lumber in Riverside.

Every project I work on has challenges and this one was

no exception. In fact, I'll be using a tool I have very little

experience with. What I plan on doing is making two different sizes of

flags: one will be 40" long and the other will be 24" long. And there

will be three of each (six total). Once you have the setup, it's not that much extra

work to make more than one.

These will all be presents for different family members:

birthdays or fathers day gifts. Yes I know I'm very early for fathers

day but I figure it's better than being late. And one of these will be

given in September later this year. With that being said, let's jump in and get started.

|

|

|

|

Let's Make Some Stripes

I borrowed this DeWalt table saw from my son-in-law. And one of the

larger ones will be for him on Father's Day. Now this is the

tool I very little experience with, but this should make life much easier because I'm

going to have a bunch of pieces. In fact

I'll be dealing with two different widths of stripes because I'm making

two sizes of flags. More on that later.

|

|

|

|

This old desk top has come in really handy and I use

all the time now that I'm finished with my

granddaughter Christmas present.

What I'm using it for this time is an 'out feed table' for

the long pieces that I'll be working with. I placed it on my adjustable

saw horses and it's just the right height.

|

|

|

I trimmed a thin piece from this black walnut cleaning up the edge. I

did this for a few of the pieces.

|

|

|

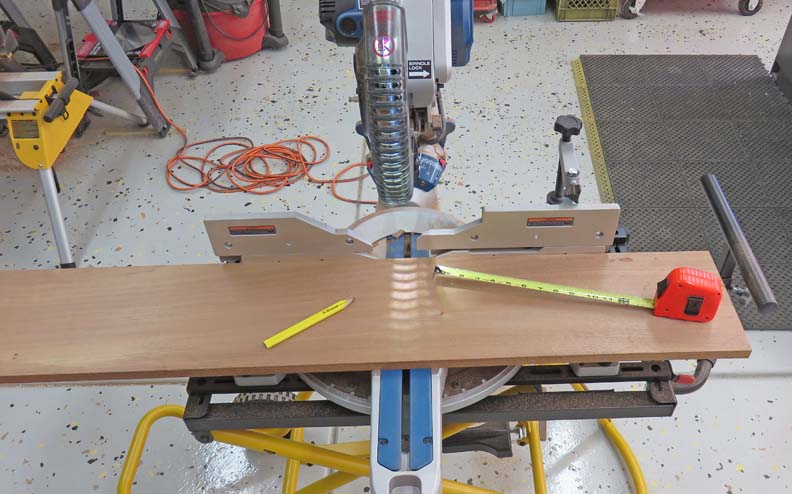

Here I'm cutting my lumber slightly oversize in length with my sliding

compound miter saw.

|

|

|

So far the table saw is working great and the large desk top is helping

me stack the boards after cutting.

|

|

|

|

The Cantons

I'll be using the black walnut for the Cantons and I've got all my pieces

that I need below.

|

|

|

|

I'm using a biscuit joiner (or plate joiner) for the

black walnut. This Porter Cable tool was given to me by my

father-in-law a few years ago and I forgot that I even had it, till

recently

that is. Now I've never used one of these before so I read the manual that came with it

to get an idea how it works. Turns out they're very easy to use and this

operation goes quickly.

A good eye will notice that I'm using my desk top for

this operation. The reason for this: turns out it's very flat so it

doubles as an assembly table as well. The pieces that you see below are

for the smaller flag and are 9 1/2" long. I used two biscuits in each

one here, but I used three on the larger pieces, which are 15" long.

To use this tool, you put a pencil mark at the slot

location and then line up the joiner with your mark. The biscuit joiner has a

small red line at it's center making it easy to line up with your pencil

mark. Then all you do is press firmly against your work piece,

pull the trigger and push the joiner into your work piece. Each slot

only takes about one or two seconds to cut, pull back on the tool and

you're done. Pretty easy, but it makes a mess.

|

|

|

|

In the Porter Cable box, there were three sizes of

biscuits, #0, #10 and #20 and I'll be using #10s. The larger the number, the larger the size of

biscuit. As you can see the biscuits are shaped like a football and they

help locate your pieces for glue-ups. Once I cut all the slots, I ran my

sanding block over the surface to remove any standing wood pieces and

then blew off everything with compressed air.

The biscuit joiner is adjustable, depending on the size

biscuits being used. You can see the adjustment knob in the picture

above (white dial) which allows you to refine the depth that's needed.

|

|

|

|

Here I'm gluing the Cantons together, again using that

old desk top. That

biscuit joiner worked out really good because the top surfaces of my

work pieces were

very

close when I pulled the clamps off. No more movement while clamping

things together. Why didn't I use this tool before?

|

|

|

|

1

2

3

4

5

6

7

8 |