|

Assembly

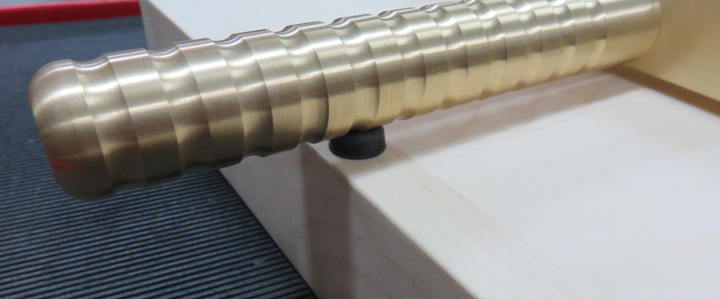

Once I had the brass pieces assembled I noticed that the

round handle was against the wooden box while it was in the lowered

position. I knew right then that the handle might put a dent or

maybe something worse might happen so I added a small rubber

pad to help cushion things. I guess time will tell if this works or not.

|

|

Once the switch is in the upper position the round handle doesn't touch

the box because I added the rectangular spacers under the upper contacts,

but you can't see them in this picture.

|

|

|

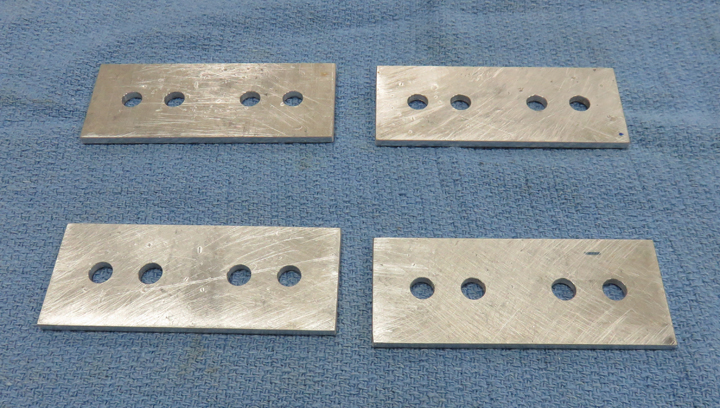

The pieces that I'm talking about above look just like these pieces and

they are both 1/8" thick. However, the pieces below I made out of

aluminum and will be used on the backside of the box.

|

|

|

|

These aluminum pieces are taking the place of washers

that might eventually crush into the soft pine once the bolts are

tightened. So in place of washers, I made these plates to help

distribute the load. I'm also using lock-nuts on all the bolts to make

sure nothing comes loose during game play.

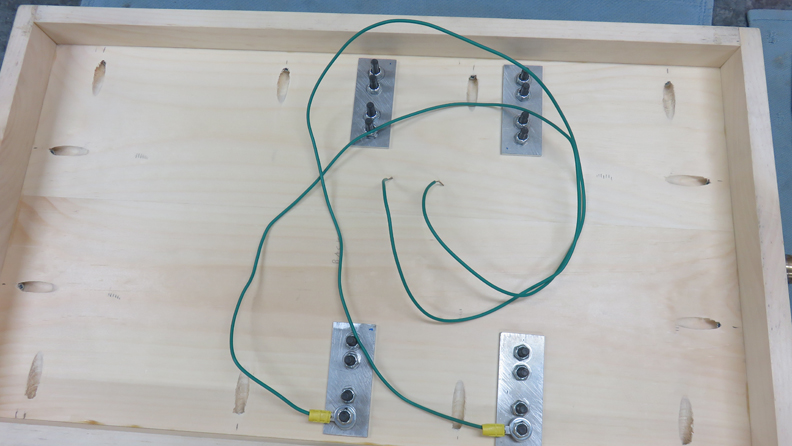

I've attached some wires to each side of the contacts

because remember, this will be a real working switch. Now it's time to take it all

apart and do some final details.

|

|

|

Here I used my router table and put a 3/16" radius on the outside edges

of the box.

|

|

|

Next I filled all the small nail holes with wood filler. The next day I

sanded everything smooth.

|

|

|

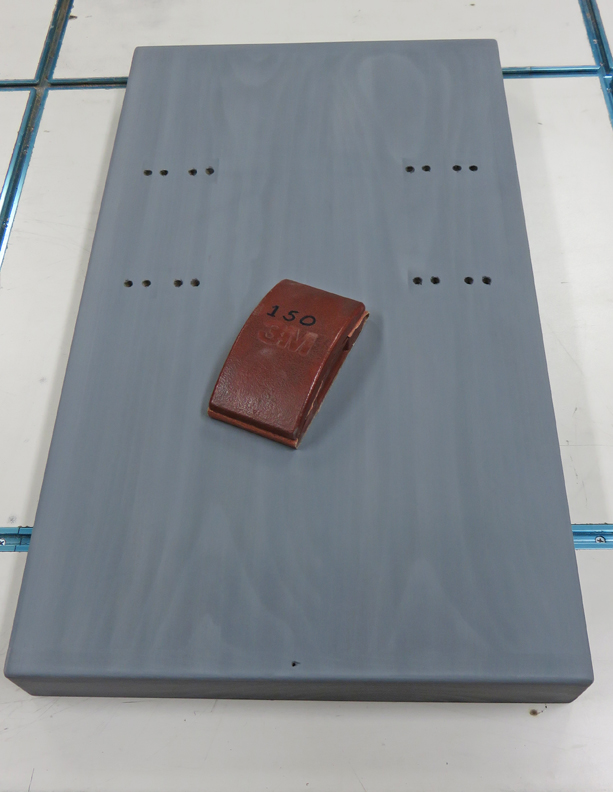

I used a spray primer and once it was dry, I sanded everything

lightly with 150 paper to remove all the dust and small high spots.

|

|

|

My daughter picked out and bought this candy apple metallic spray paint

which she thought would look good. I thought the same thing, until I

started using it that is.

|

|

|

|

This spray paint was by far the worst that I've ever

used. I could not get the paint to exit the nozzle for more than one or

two seconds before it would clog. And most of the time it would clog as

soon as I pressed the nozzle down. I tried everything I could think of

to help clean the nozzle, lacquer thinner, small pins, small drills,

larger drills (I had nothing to lose here) but nothing worked.

|

|

|

|

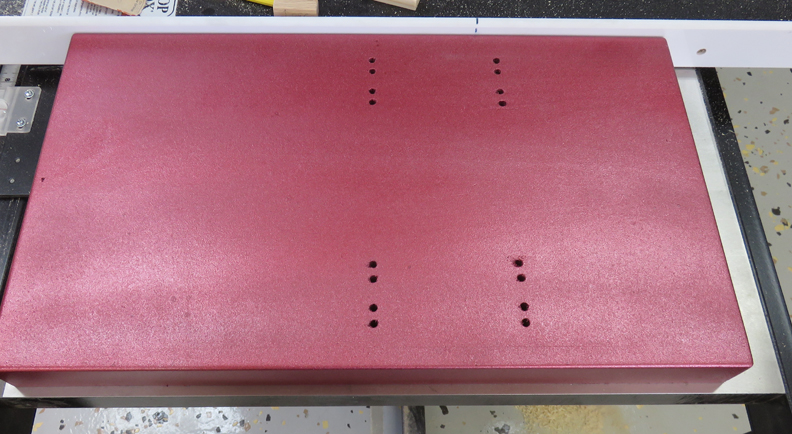

As you can see the surface looks terrible, so I sanded

it all off and used a different color red that I thought would look

nice. But Angela didn't care for this new color and they decided to sand

that off as well and use a totally different color. But once you see the

finished pictures, then you'll see why. If I only knew I could have

prevented all this headache.

|

|

|

|

1

2

3

4

5

6 |