|

Working With Metal Continued

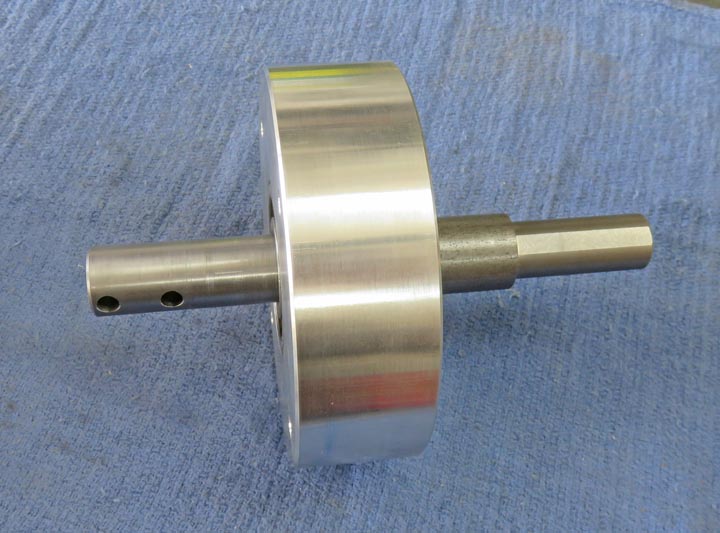

Here is bearing housing with the inside diameter finished and ready

to accept the bearings.

|

|

|

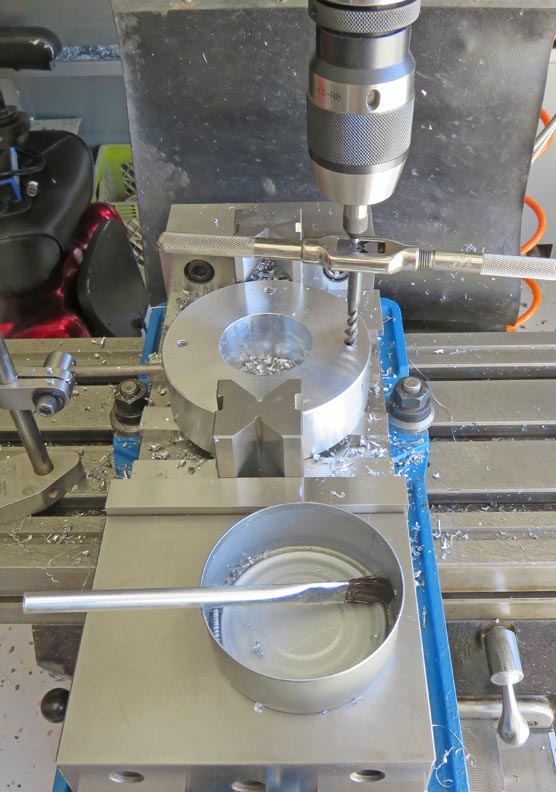

I'm putting in four threaded holes for

some 5/16-18 bolts (coarse thread). This will hold the bearing housing

to the floor.

|

|

|

|

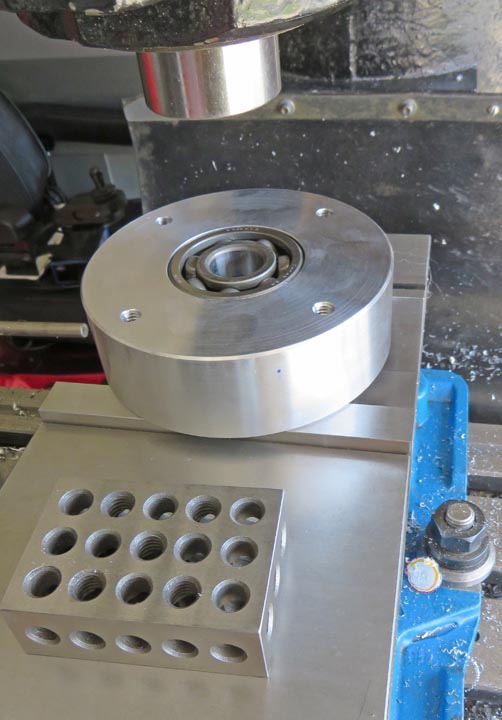

Here is what it looks like and the next step is to press

in the bearings. Speaking of bearings, I put the bearings in the freezer

overnight to make them easier to install because it shrinks them by a

small amount. Now if I hit my dimensions correctly, those bearings will

be easy to install.

|

|

|

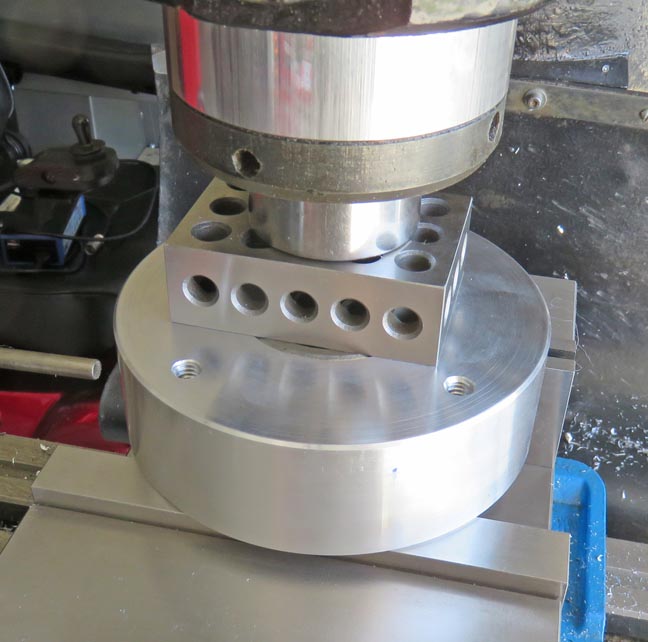

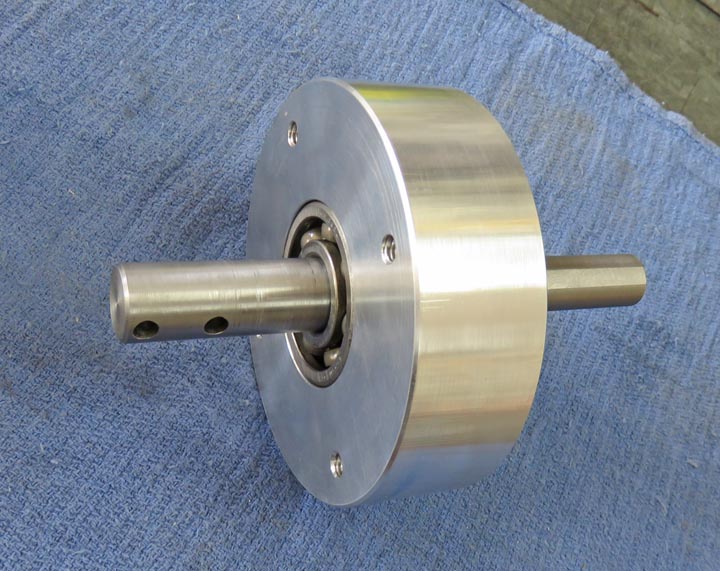

I used my milling machine to help with the installation, which worked

out great.

|

|

|

I used a 1 X 2 X 3 block to help keep things square and they both went in

perfectly.

|

|

|

These bearings are way overkill for what I'm doing here (very large and

heavy duty), but I had them sitting around so I thought I use them.

|

|

|

Here I'm putting in the bolt holes for the adapter. Those holes are

slightly over 1/4" and the same will be put into the adapter.

|

|

|

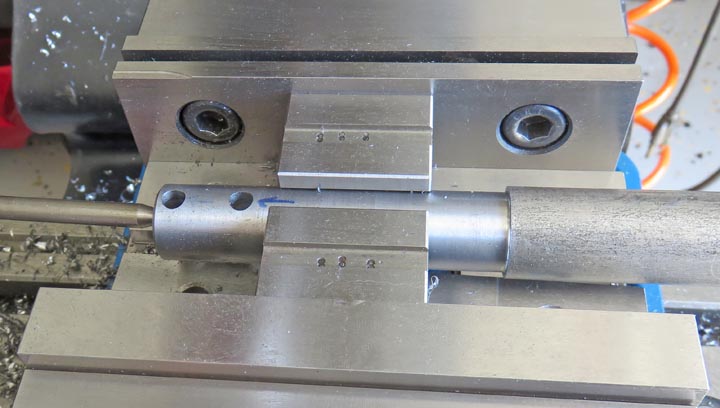

Here is the shaft pressed into the bearing housing and everything went

together great. Note the flat on the right side. I machined that for the

pulley screw.

|

|

|

The left side will stick up through the floor and the four bolt holes

will mount to the plywood.

|

|

|

Here is the adapter all ready to bolt-up to the bearing shaft.

|

|

|

|

1

2

3

4

5 |