|

Making Cake Pop Stands Continued

I had two pieces of 3/8" dowel and sure enough, they were different

sizes so I had to do some sanding.

|

|

|

This should give you a good idea of where

the dowels will be placed. The vertical ones in the center are to help

align the second row.

|

|

|

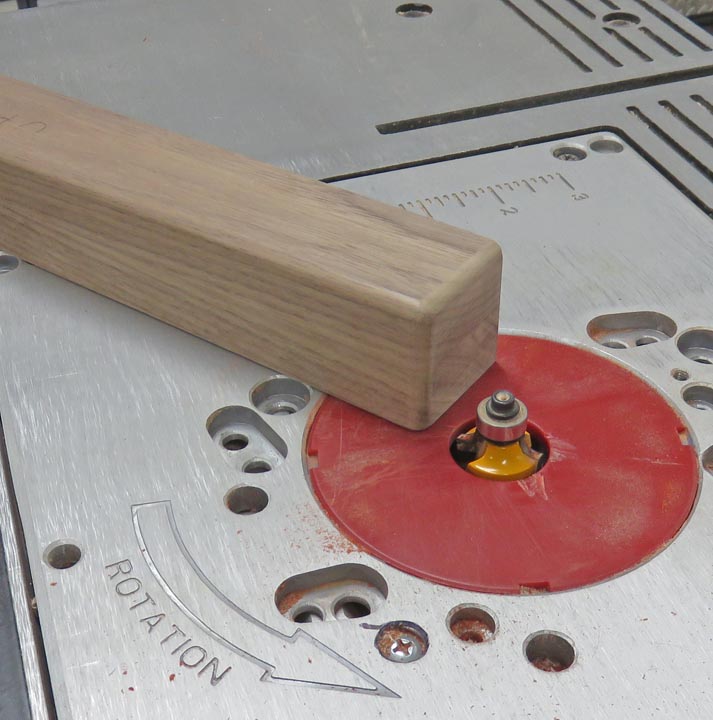

I wanted to make sure some of the edges were rounded so I used my

router table with a 3/16" roundover bit.

|

|

|

|

Glue Up # 2

I'm gluing the bottom row and second row here. And like I did before,

no glue between the two pieces.

|

|

|

Once the glue was dry, I sanded both sides with 120 grit.

|

|

|

|

Glue Up # 3

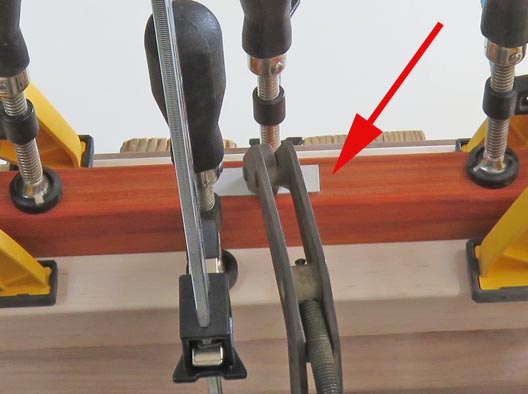

This is the final gluing with all three tiers clamped in place. And

the single top piece has dowels as well.

|

|

|

To make sure I didn't put a dent in my top piece I'm using a cardboard

shim under the clamp.

|

|

|

Both ends only needed minimal sanding until each block was nice and smooth.

Also note that only some of the edges have a 3/16" radius.

|

|

|

|

Time For Some Holes

I did some checking and I found two different size cake

pop sticks; 3/16" (.1875) and 5/32" (.156). I'm drilling the holes .191"

diameter because this way both sizes should fit. The depth is one inch

deep and there are seven on each tier, making 35 total holes.

|

|

|

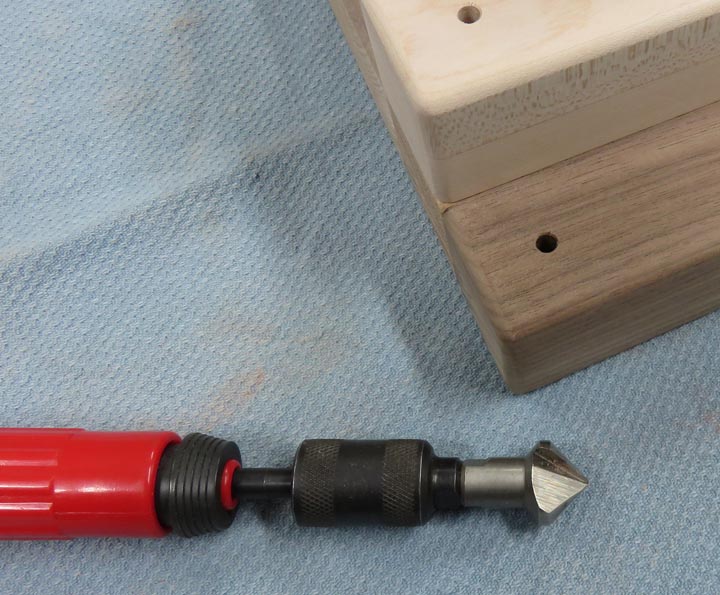

I put a small chamfer on each hole by hand. This tool works great for an

edge break that doesn't need to be very large.

|

|

|

|

1

2

3 |