|

My daughter Angela, sent me a picture of a potential

project, which was a cake pop stand. Now this was at the end of Summer

when I first saw this project but after thinking about it, I decided to

make two of them. One will be hers and the other will be her sister

Tracey.

And I'll give them as Christmas presents.

Making Cake Pop Stands

When I'm making a new project, one of the hardest things

for me is deciding on what kind of material to use and the shape of it.

And as you can see, I'll be using a lot of different species of wood

here. From top to bottom: African paduak, black walnut, maple, ash,

cherry and oak.

What I'll be doing first is making some blocks 1 1/2" X

1 1/2" X 13 1/2" long. Then I'll arrange them so I have five on the

bottom row, three on the second row and one on top. Let's get started.

|

|

|

The first thing I did was run all my

material through my planer so they were all the same size and nice and

flat. Then I ran them all through my table saw, making them slightly over my target

size of 1 1/2".

|

|

|

|

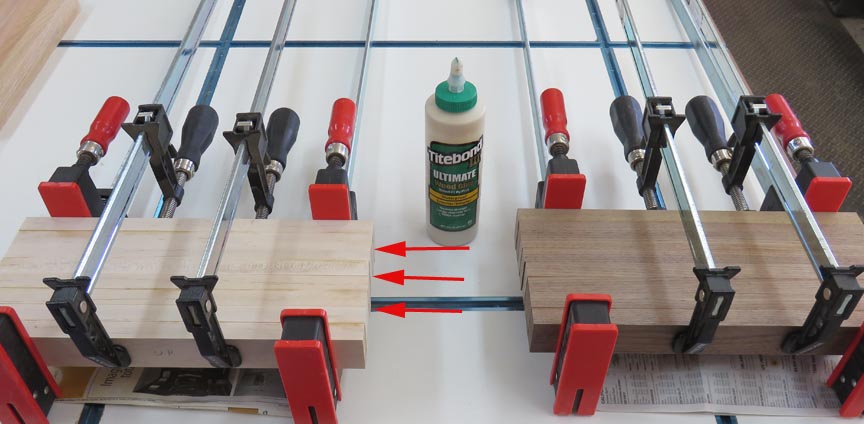

Now that I have all my pieces cut oversize, it was time

to do some gluing. All my wood is 3/4" thick so I needed to glue two

pieces together to get my 1 1/2" final size. I'm gluing four pieces

together here but I didn't put glue at each arrow. The same on the right

side as well.

|

|

|

A few days later I had all my pieces glued and now it was time to cut

them to size. This went pretty well so now it's time to cut them to

length.

|

|

|

Next it was time to cut off the excess material from each block, but one

end only.

|

|

|

I put an pencil mark on each end to help me keep track of the cut ends.

|

|

|

Here I'm measuring my work piece, which was slightly oversize here.

|

|

|

|

Once I knew how much needed to be removed, I placed my

indicator against my work stop, moved it the desired amount and clamped

it back down. The next cut was right on the money. This may be a little

extreme doing it this way, but remember that I'm a machinist.

|

|

|

|

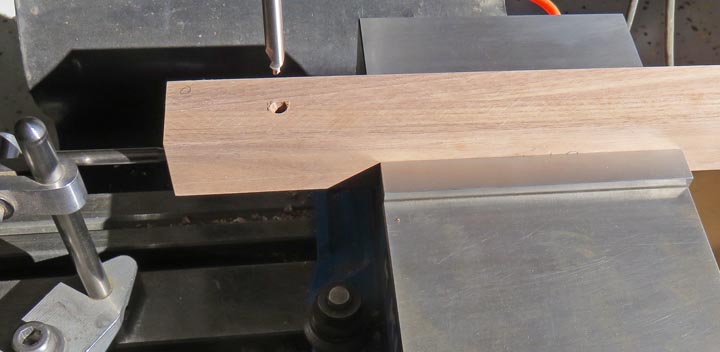

I'm getting ready to drill all my blocks for 3/8"

diameter dowel pins. This will keep the pieces together while they're

being glued. I'm center drilling one end first, then moving the table to

the other end for the second hole. This way I know all the pieces will

fit together correctly.

|

|

|

Here I'm using a 3/8" drill for my dowels.

|

|

|

|

1

2

3 |