|

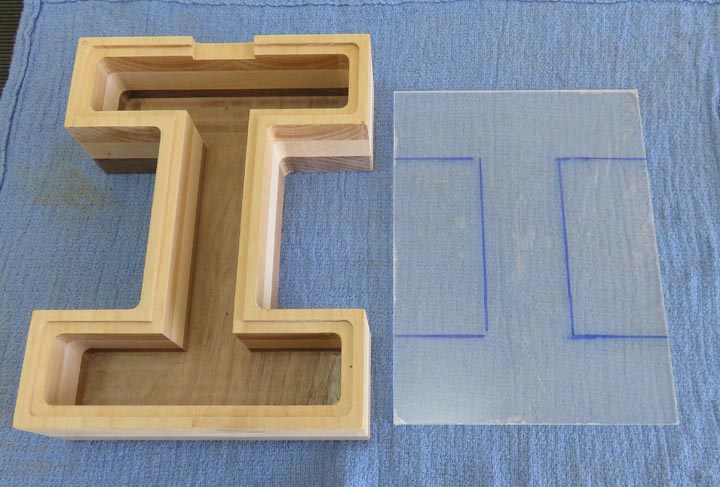

Working With Wood Continued

Here is the coin slot all finished. It's large enough for a silver

dollar to slide through just in case mom and dad have one of those old

coins.

|

|

|

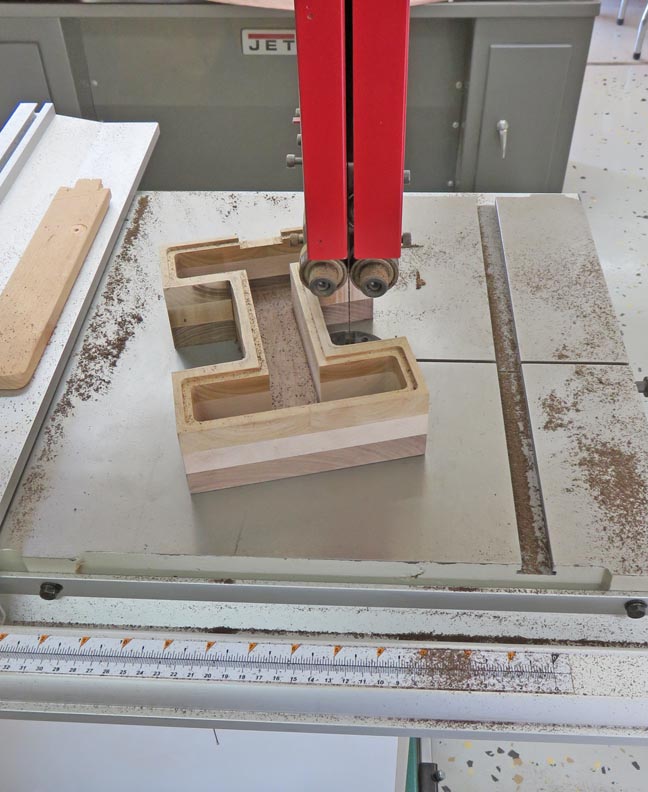

Now it's time to cut away the sides to

make the bank look like the letter "I". I used my bandsaw to rough out

the waste which went pretty fast.

|

|

|

|

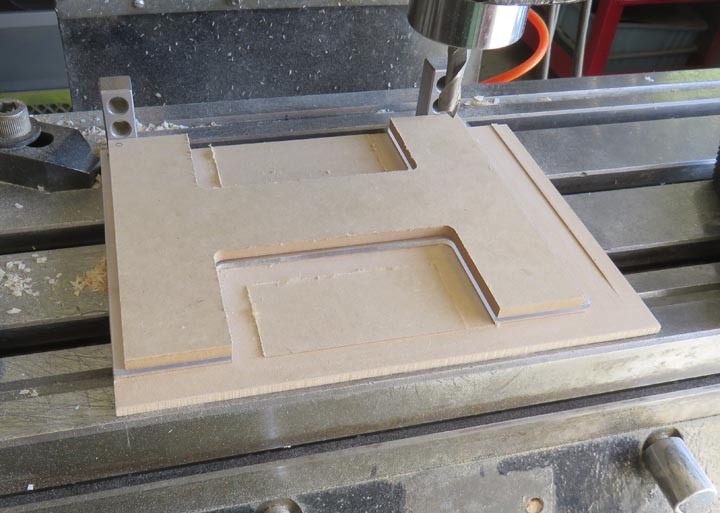

Next I used my milling machine to smooth out the rough

saw cuts. Also notice the two scrap pieces of wood that are clamped to

the sides (arrows). This is just like before when I was cutting the coin slot

so the end grain doesn't crack or splinter.

|

|

|

|

When I exit my work piece, this scrap piece keeps

everything where it needs to be (no cracks). Also notice the adjustable

parallel in the middle. This is to prevent my work piece from breaking

and to make sure everything stays true while the sides are being

clamped. Once this side was finished, I moved the scrape pieces to the

other end and repeated this process.

|

|

|

|

Working With Plastic

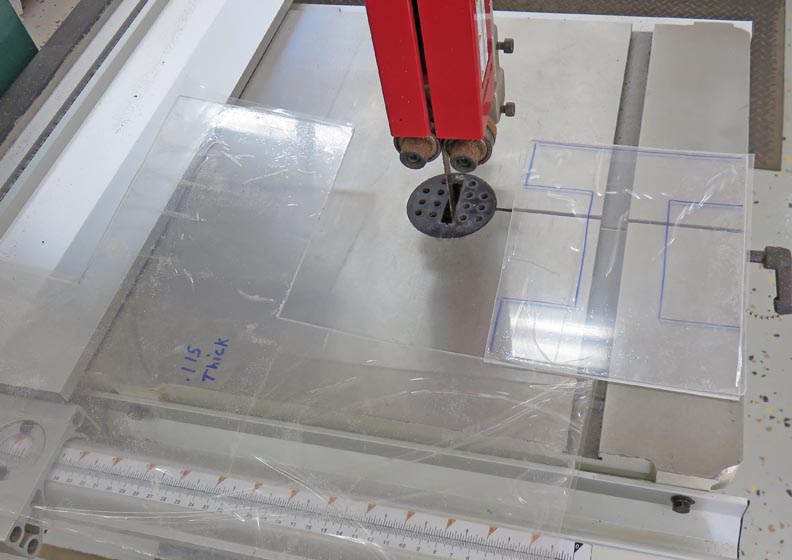

It's time to cut out the plastic that will be on the front of the

bank. Again I used my bandsaw to rough out my work piece.

|

|

|

Here I'm cutting one end of the plastic but just a minimum clean-up.

Then I turned the plastic around and cut it to size.

|

|

|

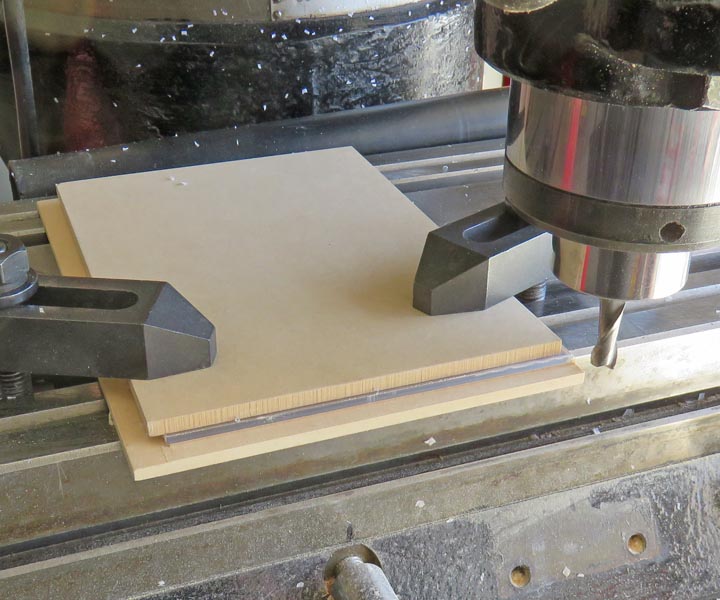

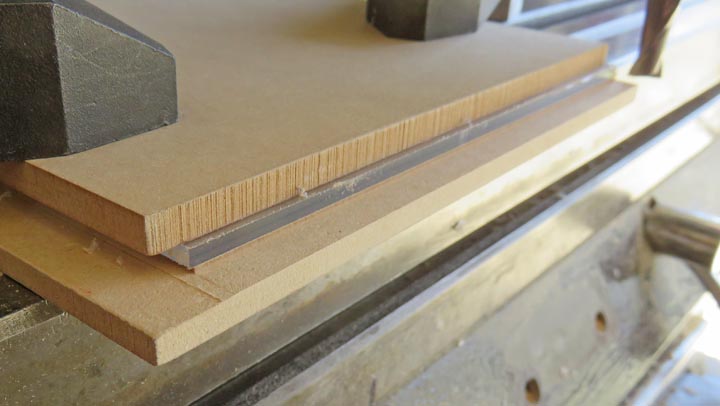

I used MDF under my work piece and another on top as a clamping plate so

it doesn't damage the plastic.

|

|

|

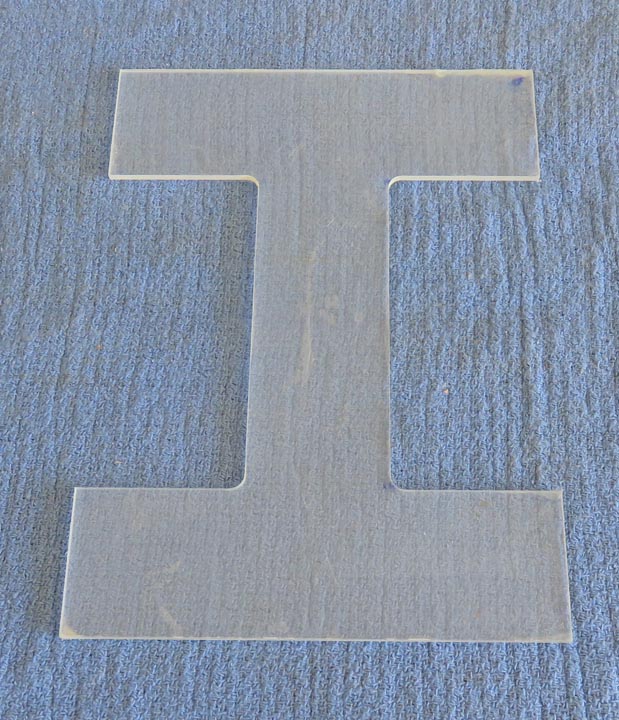

Now that the plastic is square and to size, it's time to cut out the

sides. I used my bandsaw to rough out the sides, just like I did the

wood piece earlier.

|

|

|

|

Back over to the milling machine, I'm locating the

plastic at two

spots in the back and one on the left side. This way I can remove my

work piece, do some checking (if need be) and place it back exactly

where it was before. This worked out well and things went smoothly.

|

|

|

|

Here is the front plastic piece all machined to size.

However, it still doesn't fit...yet. Notice the eight corners that are

sharp. Well, those won't work with radius corners on the wood piece so

I'll need to do more work here.

|

|

|

|

1

2

3

4 |