January thru June 2008

33 Coupe Having Fun 22 4/03/08

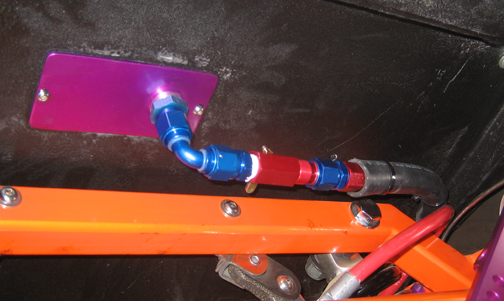

| The next item that I installed was my fuel shutoff valve,

which I should've put

in when I built the car. The valve is the longer red piece in the middle

and has a quarter turn ball valve inside with the handle on the top. I

could have mounted it in any position because the fitting that it

connects to has a swivel. To install the new valve required two

things, shortening the fuel line and adding a straight fitting. My old

fuel line had a 90 degree fitting on the end (which ended up not being

used at all) and the new one that you see here called a 90 degree coupler fitting

because it has female threads on both ends. Oh, in case your wondering

about the funny looking black stuff covering the fuel line, that's

because I had a problem and got real lucky in the process.

|

|

|

|

Let's go back a few days so I can tell you what happened. I was

getting ready to drain my fuel line to replace my fuel pump, which means

removing one fitting and replacing it with another. The fitting I'm

referring to is like the one you see above,

which goes into the gas tank. What I do first is put a bucket below this

area because when I remove the gas line, the fuel comes out and sprays

all over the place until it's completely unthreaded. Once that's done, it's time to thread on a cap to seal off the flow of fuel, which

only takes a few seconds, if everything goes right. Sounds easy but in

the process, you get soaked in gas. That's how the process should go,

but I had a different out come.

While I was unscrewing the fitting with the gas leaking all around

and soaking me, I pay close attention to

where the fuel is spraying, making sure it doesn't get into my eyes. Right

when the fitting comes loose is when you act as fast as you can and put on the other

fitting (the cap). Now I've done this a few times without any problems

but this time the braided line found it's way to the positive battery

post and the sparks flew. Remember, this is braided "stainless steel"

line and when the one end touched the terminal, the other end of the

line was against my stainless brake line making a nice ground.

Now I've got one hand on my fuel line when the sparks started flying,

along with a nice shower of gas under the car, and it's running down my arm, into my armpit

and along my side. The first thing I did was try to pull the line away

from the battery post but for some reason, I managed to hit it one more

time while doing so. This made for another set of sparks but for some

reason, most of them traveled towards the other side of the battery and away

from me. Once I had moved the fuel line a safe distance away, I reached

for the cap and sealed off the gas tank. Now if there

was ever a time that was primed to go bang, this was it, so you talk

about getting lucky!!

Here is my old fuel line with two burn marks. It was

bad enough to eat through the braided steel line and fry it (towards the

top) so this piece goes into the trash. Plane and

simple, I got lucky!

|

|

|

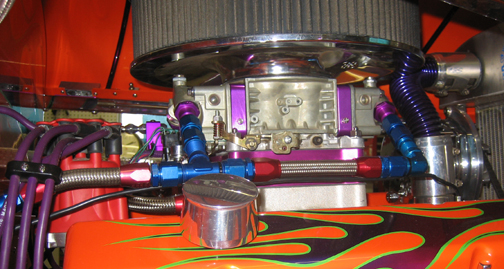

| Moving forward to the present again, this is the completed fuel line that is now finally done

(below).

It starts at the carburetor fuel bowls that have some new purple

fittings and they attach to some couplers that thread into a

90 degree fitting on the right and the T fitting (that I've been waiting

for) on the left. The small braided steel line between the two fittings

is one of the pieces that I had to make and it had to be exactly the right

length or it wouldn't work. If you've ever messed with braided steel

line, you'd know that it's not easy to end up right where you want it, so

the "measure twice, cut once" rule really applies here. One

other item that I thought would look good was some purple metering

blocks for the carburetor. These are solid aluminum and only come with

gaskets and vent whistles. To install them means swapping out my old

jets and power valves to the new blocks which only takes a few minutes.

They have the same four corner idle system as the old ones do and they complement the

other anodized pieces pretty well.

To adjust the new metering blocks, you start the engine and slowly

turn each screw the same amount till you get the highest vacuum reading

on your gage. The new parts didn't come with any instructions but this

is how you tune the Holley parts. To start off with, I ran the screws

all the way in and then backed them off one full turn each. I figured that

this should get me into the ball park and then once the engine was

running, I could fine tune it.

It was time to start the car so I hooked up both battery cables and was ready to fire up

the engine. After cranking on the starter for what seemed like way to

long, the engine finally came to life, but ran very ruff. Well the good

news was that my new starter worked pretty good but the bad news was

that the engine wouldn't stay running.

After keeping my foot on the pedal so I could warm up the car, I got

out and started tuning on my new metering blocks. After playing with the

screws for a few minutes, the engine wanted to die no matter what I did.

And you talk about running to rich!!

When you turn the screws in, this puts less fuel into the motor. Once

I had the screws turned all the way in and it still didn't want to idle,

that wasn't good. I turned off the engine and went outside to get some

air because I've never had the garage so full of rich exhaust before.

Gas maybe, but not exhaust :~]

One thing led to another and off came my new blocks and on went my

old ones. After everything was tightened and ready to go, I turned the

key and the engine ran just fine again. What the hell's up with that I

thought?

Needless to say, the picture below isn't the way the engine looks

anymore because I've sent those new metering blocks back where they came

from and got my money back. To bad because I liked the way they looked.

|

|

|

| Now that the car runs again, it was time to take it out

and make sure it ran right. When I got off work on Friday, I took it for

a test drive around town just to make sure things worked and that I

didn't have any leaks or funny noises.

The next day, Saturday, we took the car to a show in Moreno Valley. And I'll have to say, I was nervous because thoughts of

getting towed home were still on my mind. Everything went just fine that

evening so

check back in a week or so and I'll have another update for you about

that show.

|

|

1

2

3

4

5

6

7

8

9

10

11

12

13

14

15

16

17

18

19

20 |

|

21

22

23

24

25

26

27

28

29

30

31

32

33

34

35

36

37

38

39 |

|

40

41

42

43

44

45

46

47

48

49

50

51

52

53

54

55

56

57

58 |

|

59

60

61

62

63

64

65

66

67

68

69 |

|