January thru June 2008

33 Coupe Having Fun 19 4/03/08

One of the best shows Iíve ever been

to since Iíve had the car running is the ďWings and FinsĒ aircraft

& car show held at the Riverside Airport. We had a great time there

last year and Iíve been planning to go again this year, which was

held on March 29th. This show has a huge variety of new

and older vintage aircraft along with a big car show, lots of

vendors and good food too. Last year they had about 300 cars and

beautiful weather to go along with the 80,000 people that showed up.

The show is free to the public, which is why they have such a good

turn out.

The time between our last show and

this one (Wings and Fins) was about three weeks, so I thought Iíd

take this opportunity to change a few things on the car before I

went. Why change things you ask? Plain and simpleÖIíve been bored!

The things that I wanted to do or

change on the car were easy, but sometimes finding the time can

through a wrench in the works. The changes would be made to the

engine compartment and one thing in the rear of the car, which are:

painted valve covers, spark plug wiring looms, starter,

carburetor spacer, battery tray and a few other minor things.

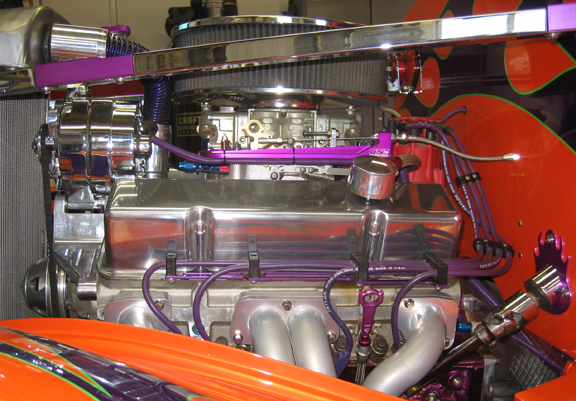

Here is what the engine looked like

before the changes. If you look close, you can see a throttle stop

right above my purple throttle bracket which happens to be a

stainless bolt. The bolt threads will be covered by a new

anodized piece that I made and right below the throttle bracket is

some linkage that goes to my throttle position sensor (TPS).

|

|

|

|

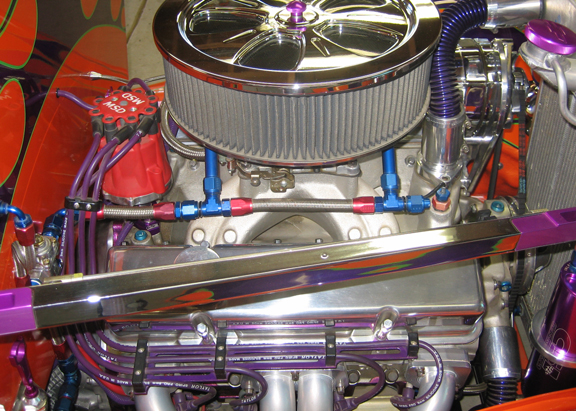

Moving to the other side, notice the purple sparkplug

wiring loom. I'm going to change that out for a chrome one. I like

contrasts and thought the chrome ones would look better against the

painted valve covers than these would. I'm also going to change the fuel

line that runs to the carburetor.

|

|

|

I ordered up the new parts and also

made a few items as well. I wanted to send in a few aluminum parts

to get anodized purple (what a surprise) and polish a few others.

One of the items that I thought would look good anodized was the

carb spacer, which I bought from

Reher Morrison. This

spacer is a two-piece unit which is comprised of one piece measuring

ĹĒ and the other being one inch thick. The top piece is called a

reversion plate and the bottom is more or less just a spacer,

stacking up to a total of 1 ĹĒ and brings along some Pro Stock

technology with it. Reher Morrison claims that using this spacer

combo increaseís horsepower and pulls more fuel from the carburetor.

I have no doubt that it will because these guys have been building Pro

Stock engines for over 35 years.

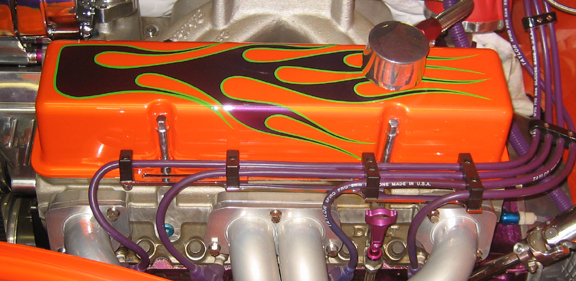

One other item that Iíve wanted to do

for almost two years now is to have some valve covers that are

painted the same color as the car and to have the same graphics on

them too. The first person I thought of was the guy that originally

did the flames on the car, which makes since because he did a good

job. The first step was to spray them orange, and a week later,

Bart, my paint guy had them finished. Then Bart was nice enough to

drop them off

with the graphics guy for me. After waiting for over a year and a half and

two phone calls later, I decided to give them to someone else.

Larry told me about a local guy, Stan

Howton, and after talking with him, Stan said that he could do them

in a week. One thing led to another and sure enough, Stan had them

finished. And he did an awesome job!

They have the same colors in them (blue and

purple) as the car does and I'm very happy with them. I also

shinned up the valve cover hold-downs because they were getting a

little dull.

|

|

|

Once I had the box of anodized parts

back, the carb spacer was first to be installed. I had to hand trim

two of the three gaskets because the spacers had been CNC

milled and the wall thickness was much thinner than any normal spacer,

leaving the gasket hanging into the plenum area. Reher Morrison told

me about this cut-to-fit gasket process so it wasnít a surprise, but takes time so you donít

cut too much or rip it. The gasket surface ended up being less than

half of what it was originally so I hope it doesnít leak.

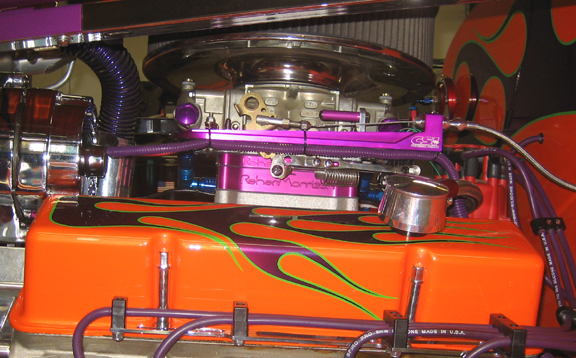

Once the carburetor was on, I noticed

that I would have to lengthen two of the four new studs that hold the carb down with because I didnít take into account my throttle

bracket thickness (1/4"). After cutting and welding on some longer pieces,

I was back in business. Also notice the new purple spacer I made coving the

threads of the throttle stop bolt.

It's hard to see in this picture but I shinned up the TPS bracket on

my buffing wheel too along with the heads of a few bolts.

|

|

|

Now that the carburetor is installed, it

was time to install some new fuel inlet fittings that I thought would look nice

(purple). This meant that I wasnít able to use my existing duel fuel

lines so it was time to make a new one (which was the plan the whole

time). I bought a few new AN fittings and some braided steel tubing to

make up my new fuel lines but one of the fittings (T fitting) was back

ordered. After calling Summit Racing and asking them about them drop

shipping the fitting directly to my house, they assured me that it would

arrive in a couple of days instead of a couple of weeks (back ordered

items take much longer if you donít call). This was great news so I

placed my order for all the stuff I needed with the guy on the phone.

A few days later, everything came in,

except my T fitting, but I still had a few days before the show, so I

worked on other areas of the car to get ready for the big day. I also installed my new sparkplug wiring

looms which are now chrome. When I

took the old looms off, I took the time to polish all the stainless

screw heads that hold on the black wire separators. And while I had the buffer all warmed up, I polished the

two hold down screws on my distributor cap too. Itís the little things that

make the difference. And again, I was bored!

|

|

|

|

Things were coming together pretty good but one thing I didn't plan on was

my throttle cable being to short after I installed the carb spacer. This

wasn't good news because in two days, I'd needed to be ready so this

meant fixing what I had. The throttle cable assembly has two main parts,

the cable and the cable housing. After pulling the cable loose so I

could do some measuring, all I needed was about a half inch longer cable

housing to make it work. I started pulling the housing out of the

aluminum adapter a little at a time making it longer and longer each

time I moved it. I should have stopped on my last try because I

accidentally pulled the aluminum adapter off the end of the housing. No

big deal I thought, I'll just slide it back on. This sounded good but

the housing is made out of braided steel (like my fuel lines) and when

it exited the adapter, the end of the cable housing frayed out twice as

big as the opening was.

I was in trouble now unless I could somehow get this housing back

into the adapter. After trying to persuade it back in with a small flat

screwdriver, I quickly found out this wouldn't work so it was time to

get serious. I started digging through stuff till I found a bronze

bushing that happened to have the same size inside diameter as the

outside of the housing. My plan was to cut the bushing through one wall

only, and then spread it open enough to slide it over the housing. I

then used some pliers to squeeze the bushing shut again and now all I

had to do was slide it towards the frayed end. Working the bushing

slowly towards the end made all the stainless wires come together on the

housing, allowing me to maneuver the adapter back in place.

Once I had the throttle cable working again, I cut the bushing off

and was back in business. Now all this took a couple of hours because I tried a few

other things that didn't work before this. But it seems like you try all

the easier stuff first in hopes that it will work. After carefully placing the housing in the

correct spot, things seemed to work just fine so I was happy again...kinda.

All this extra work ate up precious time so I wasn't able to install my

new starter or work on my battery tray. And now all I could think of was

if my fuel fitting would arrive the next day or not.

|

|

1

2

3

4

5

6

7

8

9

10

11

12

13

14

15

16

17

18

19

20 |

|

21

22

23

24

25

26

27

28

29

30

31

32

33

34

35

36

37

38

39 |

|

40

41

42

43

44

45

46

47

48

49

50

51

52

53

54

55

56

57

58 |

|

59

60

61

62

63

64

65

66

67

68

69 |

|