By working the all-thread back-and-forth like a file, I was able to open

the hole enough for an electrical cord to pass through. Whatever works

ya know!

|

|

|

|

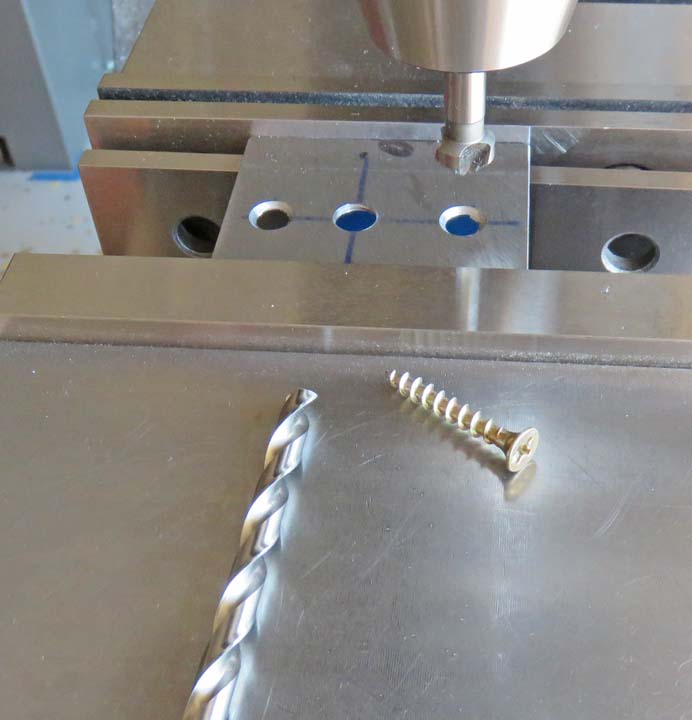

Adapter Plate I placed my wood piece on my milling machine table and

worked this end until I had it level. I didn't use my milling machine to

cut anything, I used my belt sander, file and sanding block so both ends

were parallel.

|

|

|

What I'm getting ready to do is make a contoured piece to fit on one

end. This piece will have 1/8" pipe threads and will be held down with some

screws. This piece is made out of 1/16" steel.

|

|

|

|

Here I'm tapping the pipe threads. Now all I have is a

tapered pipe tap but these should have been straight pipe threads. That

means I'll have to be careful not to go too deep on these threads.

|

|

|

I bought these pipe nipples at the hardware store so I have some

choices. And these pipe nipples all have straight pipe threads.

|

|

|

|

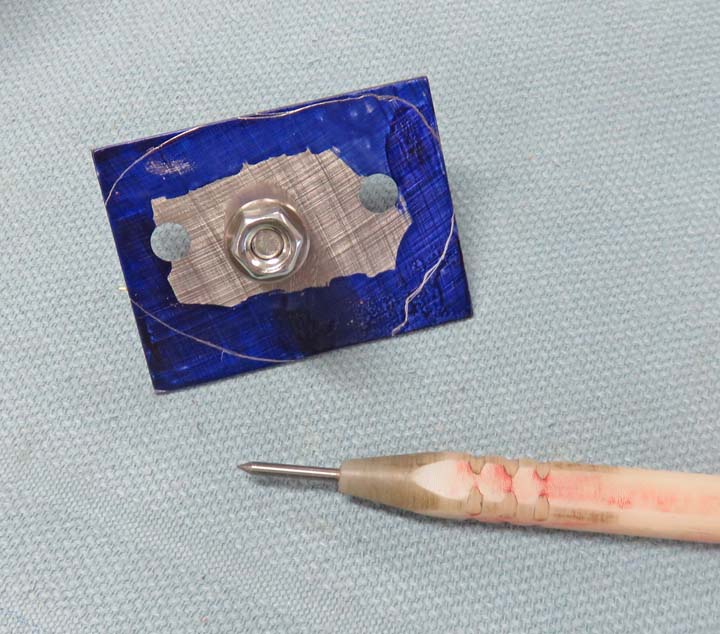

What you see below is my 1/16" steel end piece but I

needed my 1/8 pipe thread centered in my piece of twisted juniper. To

make that happen I made this small bushing that is 5/8" outside diameter

and the inside diameter is the same as my 1/8" pipe thread. And with a

pipe nipple threaded into my steel plate, I used a 1/4-20 bolt through

the center to hold everything together.

|

|

|

Now I can insert the bushing into my wooden piece and it will stay

centered while I do some layout.

|

|

|

Here I'm drilling and chamfering some holes to fasten the steel plate on

with.

|

|

|

Now I can transfer these holes to the wooden piece.

|

|

|

Here I've scribed a line from my piece of juniper and now it's time to shape

it.

|

|

|

|

1

2

3

4

5 |