|

I'm going to make a portable vise for my son-in-law

Matt, for Father's Day. This idea came from working at my daughters

Escape Room and trying to find a place to cut some metal tubing or some

other kind of metal. What Matt came up with temporarily was to use some

hand clamps and an old wooden pallet and then start cutting. This works but

you have to kneel on the ground while doing this and that's no fun.

That's when I had the idea of making some kind of

portable vise stand that could be moved around as needed which would

take the place of that old pallet. What I needed first was something to

use as a base and thought an old steel rim would work good for this. The

one that you see below was given to me by a small tire shop near my

house so I took it home to clean it up.

Building A Portable Vise |

|

|

|

I also needed two other pieces that I could weld some

tubing to and

I remembered that I had this piece leftover from working on my

33 Ford

Coupe. This piece below was used to help me install my five speed

transmission many years ago and is 3/16" thick X 6 1/2" X 15" long. This

piece of steel should work perfect for welding some tubing to once I cut

it to the size I need.

|

|

|

|

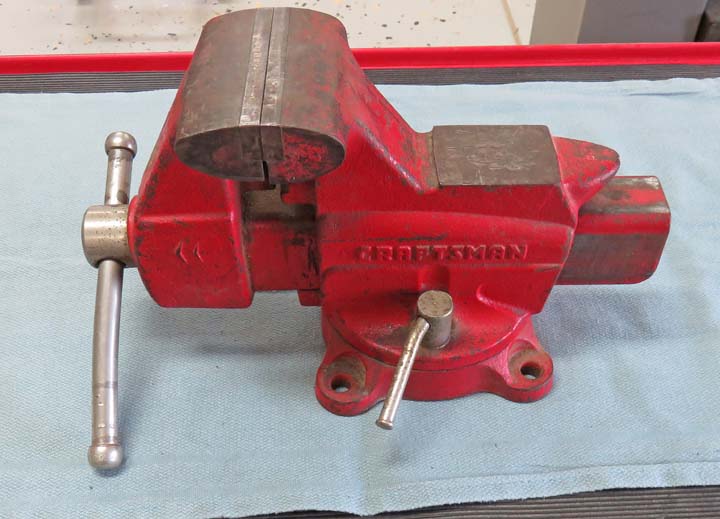

Here is my old Craftsman vise that I bought new in the

mid 70's while working on my 71 Camaro. This Sears vise has worked

really well over the years but eventually I bought a larger one when I started

working on my 33 Coupe. Anyways, I'll be using this old one for the portable

vise on this project.

|

|

|

|

I'm cutting the steel plate with my metal chop saw which made

quick work of it. I'll need two pieces, one that will go under the vise

and the other will be bolted to the wheel.

|

|

|

|

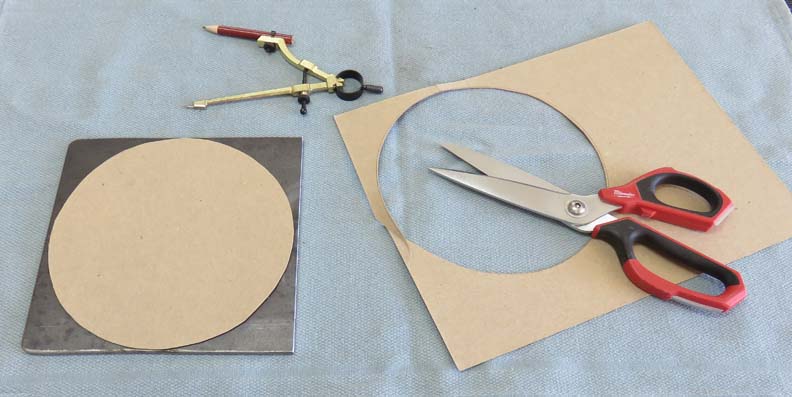

The piece that will be bolted to the wheel is going to

be just over six inch's in diameter. Here I'm cutting out some cardboard

as a template, then I traced around the template with a marker for

reference.

|

|

|

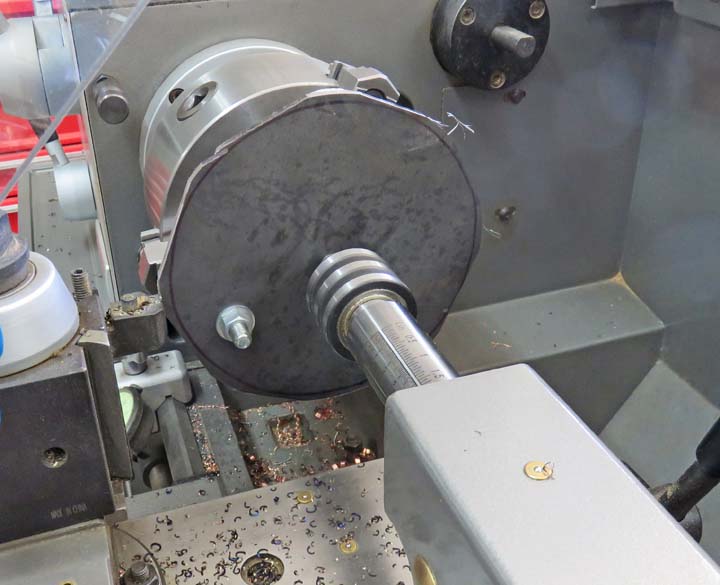

I'm cutting away all the excess material that I don't need and then I'll

turn it on my lathe.

|

|

|

I used a bolt in one of the existing holes and used it as a dog against the chuck jaw so it doesn't

spin when I'm machining it.

|

|

|

After a few minutes my piece was nice and round.

|

|

|

|

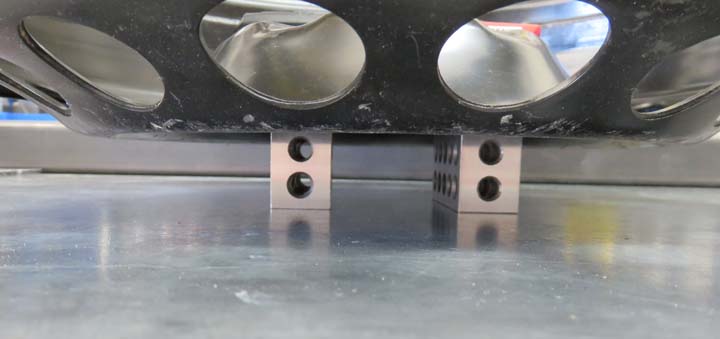

I've placed my round piece under the wheel, made sure it

was level and then marked the five hole locations with a marker. To make

sure the round piece was elevated I used some 1 X 2 X 3 blocks. The next

picture will show the blocks.

|

|

|

|

Here are my 1 X 2 X 3 blocks sitting on my bench with

the round piece on top of them. And then the wheel is sitting on the

round piece keeping it in the correct position while I marked it. But

these marks are for reference only.

|

|

|

|

1

2

3 |