|

Working With Steel Continued

The end pieces will need to be about 1/2" shorter than the others because

of the bends on each end (arrow).

|

|

|

Only one end needed to be cut on the L

pieces, which went

fast.

|

|

|

|

I'm using a piece of round bar clamped to the cage to get the proper

location for the end pieces (arrows). Once I had my end piece in the

right spot I nailed it in place. After both end pieces were welded, I cut

12 side pieces (which are straight) and welded those three inches apart as well.

|

|

|

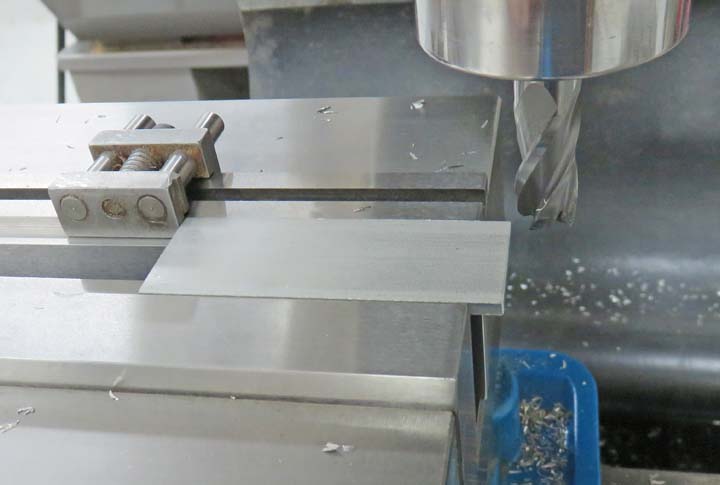

Here I'm machining some 1/8" stainless steel that will be used as clamps

to hold the cage to the house.

|

|

|

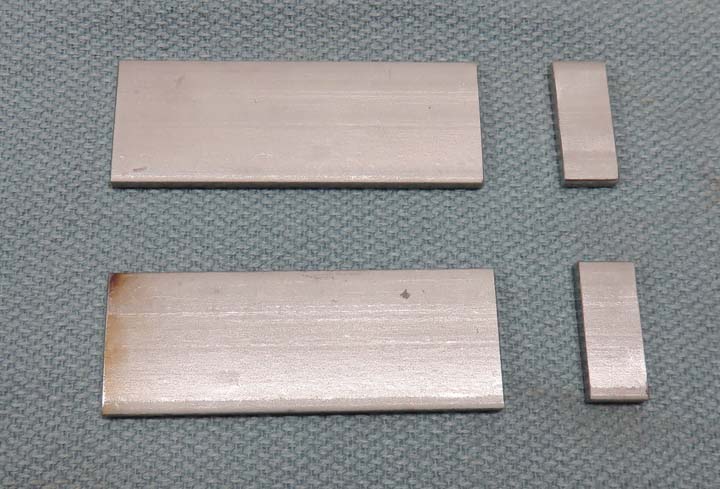

These are simple toe-clamps that should work pretty good for this. The

small piece is 3/8" long, matching the round bar diameter.

|

|

|

Here they are welded and now I just need to add a clearance hole for

some

1/4" bolts.

|

|

|

|

I did a test fit with the cage and need to add about 3

1/2" to the bottom because the ground is uneven. Here I'm bending two more

pieces that will help level the cage.

|

|

|

These pieces didn't take long and should work nicely. Also, these two

pieces will be buried in the sand and won't show.

|

|

|

Now it's time to add a protective coating to the bare steel. I happen to

have the primer and clear already but I wanted the color to be glossy so

I bought some black paint.

|

|

|

Here is my paint booth. It was a windy day which is why there are so

many smaller pieces of wood holding the trap down.

|

|

|

|

1

2

3 |