|

My daughter Tracey requested a food serving tray and

sent me a picture of one that she had in mind. Turns out it was very

close to the

fruit bowls that I made a few months

ago, so I told her she could have the extra one. But she had

two requests after looking at the one I had: first she didn't want the

full radius at the top and second, she wanted some slots that she could

put her fingers into so she could carry it. I told her no problem that I

could modify it to her liking.

Modification Time

Here is the fruit bowl I made awhile back and now it's

time to implement some changes to it.

|

|

|

A close-up of the full radius at the top.

I have a plan to remove it to make the top surface flat.

|

|

|

|

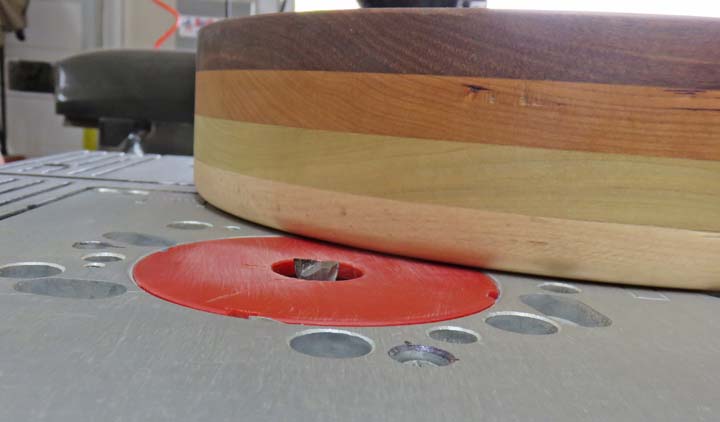

I thought that I could take off small amounts of

material on my router table but quickly found out that wasn't a good

idea. I placed some shims under the area that I cut so the bowl would

still sit flat however that didn't work very well.

|

|

|

|

Plan B I started thinking of ways

to remove this radius and decided to use my table saw. I clamped a large

piece of MDF to the fence and then used a smaller clamp as my work stop

(arrow). Then I slid the bowl into the saw blade nice and slow until it

hit my work stop. At that point I have one hand placed inside the bowl

putting pressure towards the fence and rotating the bowl with my other

hand. I only took about half a blade width each time and after about

four cuts I had a nice flat surface. This worked fine but was very scary

because of how close my hand was to the blade.

|

|

|

|

Modification Time Continued

I had some burn marks on the maple because of how slow I was rotating my

work piece but those disappeared quickly with my DA sander.

|

|

|

And there we go, time to put a smaller radius on the top now.

|

|

|

I used a 1/8 roundover bit for the top surface which goes very fast.

After a quick sand it was time to put some slots in.

|

|

|

|

Here I'm laying out for my two slots. First I put lines

in the middle, then I put a line at both ends of my slots. Once the

wood had lines in them, I ran my pencil over them so I could see them

better.

|

|

|

|

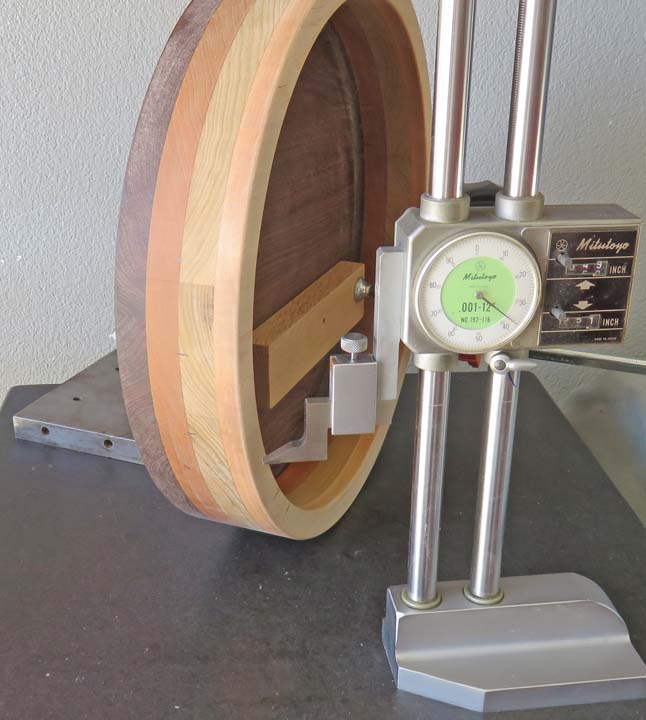

To cut these slots, I had to arrange my milling machine

so I could hang my work piece over the edge of the table. Notice the

head is turned and the ram is extended outward as far as I could get it.

This was just enough so I could get to my work piece.

|

|

|

|

1

2 |