|

Making A Foot Step Continued

I'm using the table on my milling machine to clamp the

sheet metal down. I placed the metal between two pieces of wood making

sure I could just see my layout line and then used a sheet metal tool

made by Vise-Grip to bend it with. I bent the metal a small amount,

moved over a few inches, and then repeated this process. I did this

until the bent surface was at approximately 45 degrees.

|

|

|

Next I used my soft-face hammer to finish

the bend to 90 degrees. I did this for all four sides.

|

|

|

I left the bent edge slightly long and then trimmed it to length after

all the bending. This way I was sure it would fit correctly.

|

|

|

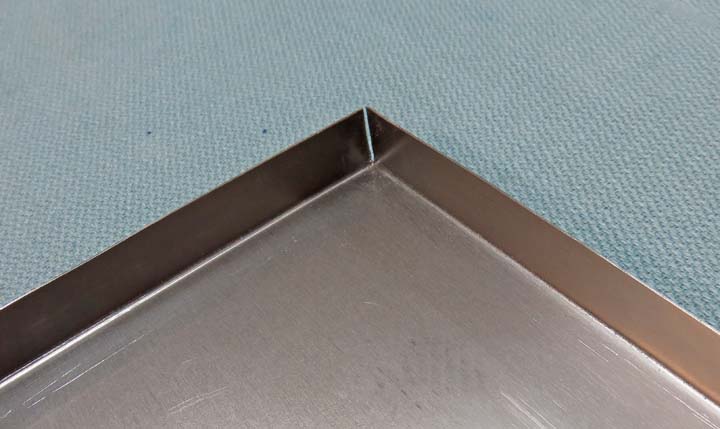

Good clean bend with some nice fitting corners.

|

|

|

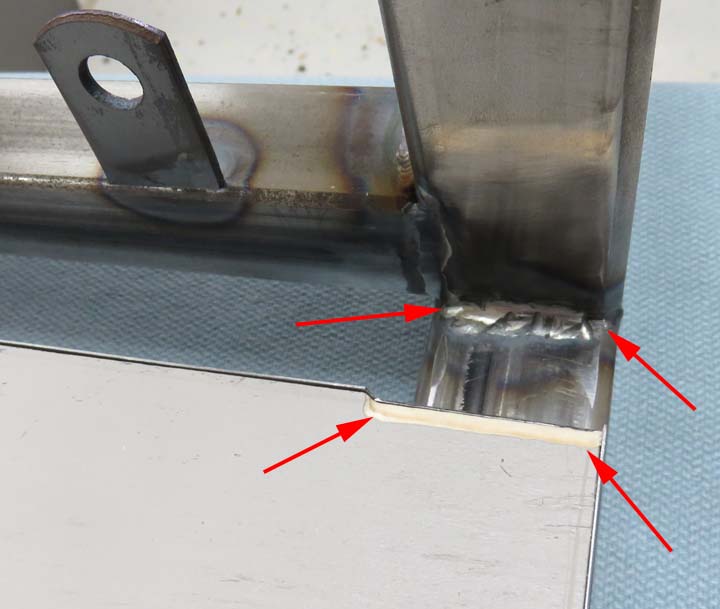

The two corners that sit against the chair frame needed to have a small

amount of clearance because of some weld.

|

|

|

I ground the weld a small amount and now the step fits just right.

|

|

|

I'll be using these plastic caps to cover the open square tubing in four spots,

two at the food rest and two at the top of the chair.

|

|

|

Here you can see the foot step is installed along with the two end caps.

If you look close you can see I used two screws per side to hold the

sheet metal to the plywood.

|

|

|

Here is a better look at some of the screws. And at this point the foot

step is finished.

|

|

|

|

1

2

3 |