|

Working With Metal Continued

I added a small chamfer to the back of each stainless piece to act as

a lead-in when it's time to install them. This will help keep them

straight and won't shear any wood when the go in.

|

|

|

These measure .400" long and are ready to

be installed. Now it's time to work with some brass.

|

|

|

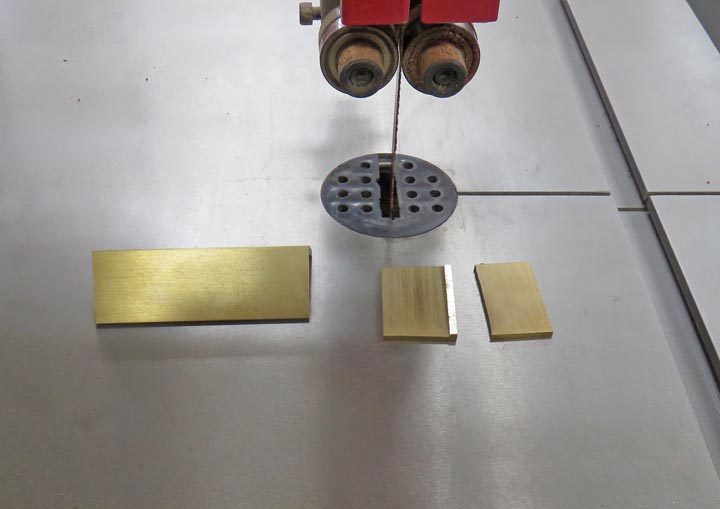

I cut off some pieces from the angle brass and then cut them once again

to what you see below. The brass thickness is already 1/8" which means I

don't have to machine that dimension.

|

|

|

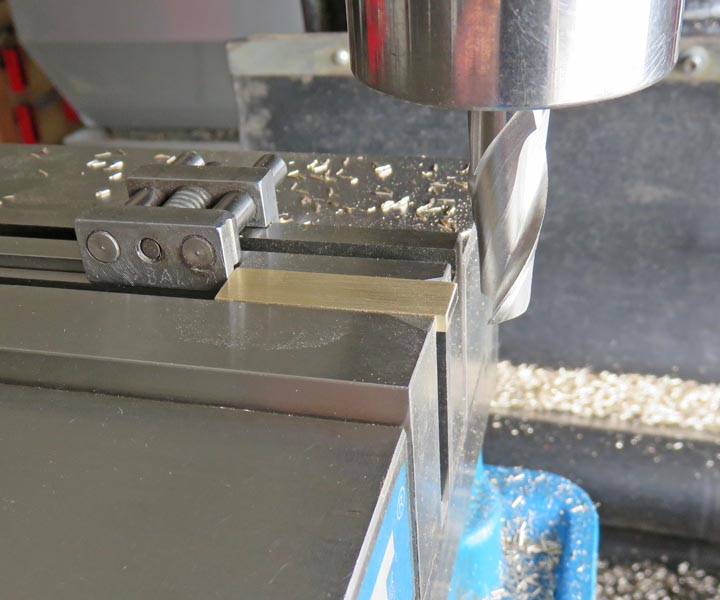

Here I'm cutting my pieces to about 1/2" wide, which is oversize.

|

|

|

Next I placed four at a time in my vise to machine them to size.

|

|

|

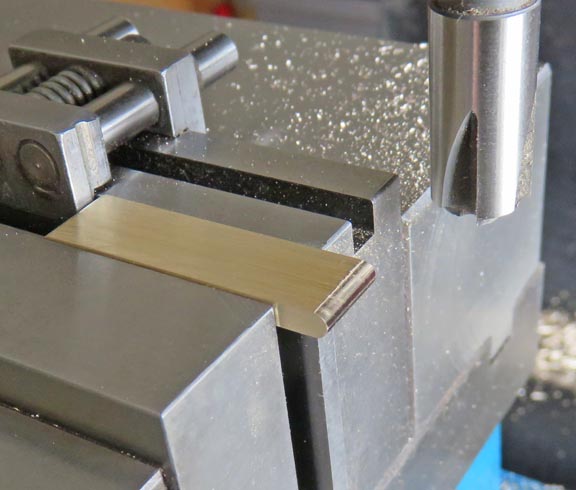

Here I'm cutting each one to 1.500" long, which will match the slot

length. Now I need to put a full radius on each end.

|

|

|

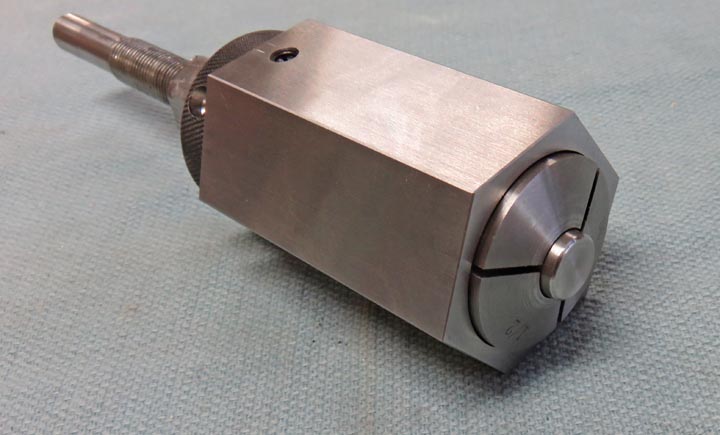

This is the tool I'll be using to cut a radius on each end of my brass

pieces. This is called a corner-rounding end mill.

|

|

|

This end mill has a 1/16" radius and once I machine both sides, this

will give me my full radius on my brass pieces.

|

|

|

Here you can see my brass piece that has my desired radius on it. Once I

deburr both sides, it will fit my slots in the clock face.

|

|

|

Here is what my finished brass piece looks like after deburring.

|

|

|

As you can see, it has a full radius on both ends. These came out as

expected and didn't take that long. Now it's time to work on some wood

again.

|

|

|

1

2

3

4

5

6

7

8 |