|

Working With Wood Continued

Here you can see the bubinga a little better. And with the

construction process like I have it, I know that my pieces will be

strong.

|

|

|

I used my thickness planer one more time

to give each surface a clean-up cut only.

|

|

|

I drew my layout circle one more time after it was removed by the

planer.

|

|

|

Next I drilled a 5/16" hole through my work piece, which will be used

for the clock mechanism and as a tooling hole.

|

|

|

Then I used my bandsaw to cut on the line. At this point, my work piece

is 13 3/4" diameter.

|

|

|

|

I'm going to use my lathe to machine the outside

diameter. However, when I held my work piece up to the face plate, the

work piece was too large to

spin on my lathe.

Oh know! Now what?

Well, I might have a solution for it, but it's a little

unconventional.

|

|

|

|

Making More Clearance

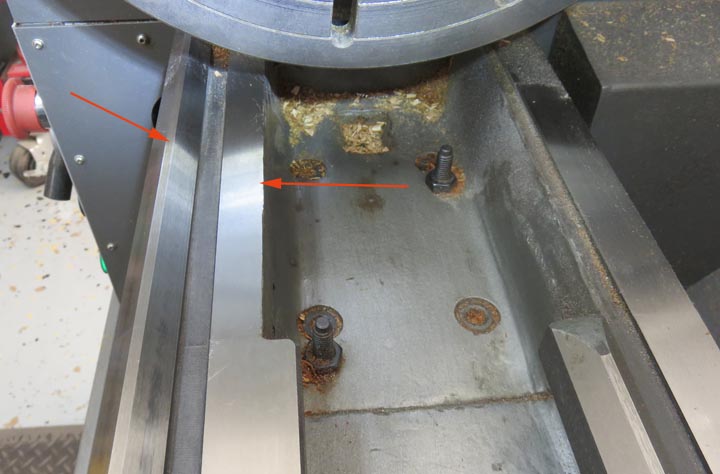

The arrows are pointing to the spots that were in the way of my work

piece. Now I've

run into this dilemma before but this time I'm going to take action and

fix this problem.

|

|

|

Notice and difference? I took my grinder to those two areas and removed some

cast iron, giving me a little more room.

|

|

|

|

Now before you start shaking your head at my decision,

just know that the carriage doesn't ride along this area so it won't

affect function or accuracy. But if it would've affected either one, I

would not have done this.

|

|

|

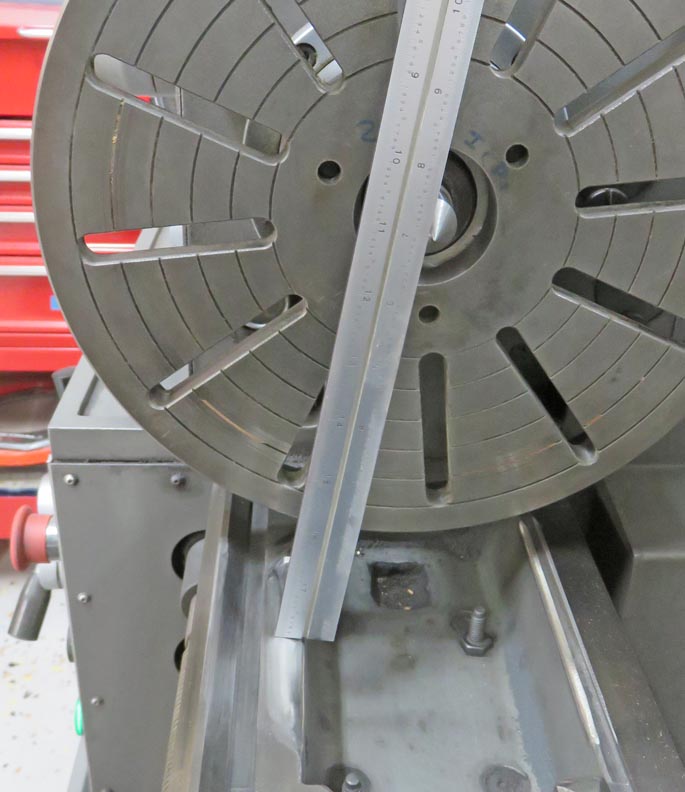

Here I'm measuring after grinding and I've gained over .200" (almost

1/4") which equates to almost 1/2" on the diameter.

|

|

|

|

1

2

3

4

5

6

7

8 |