|

Working With Metal and Plastic

I made this adapter out of aluminum which will be used

on the motor. The outside diameter is 1/2" which is for the pulley, and

the inside diameter is 6mm (or .236") for the motor shaft. The pulley has a small

flat on it so I added a setscrew so it holds better.

|

|

On the other side of the adapter I put a

dimple for the pulley's setscrew to go into. This setup should work

great.

|

|

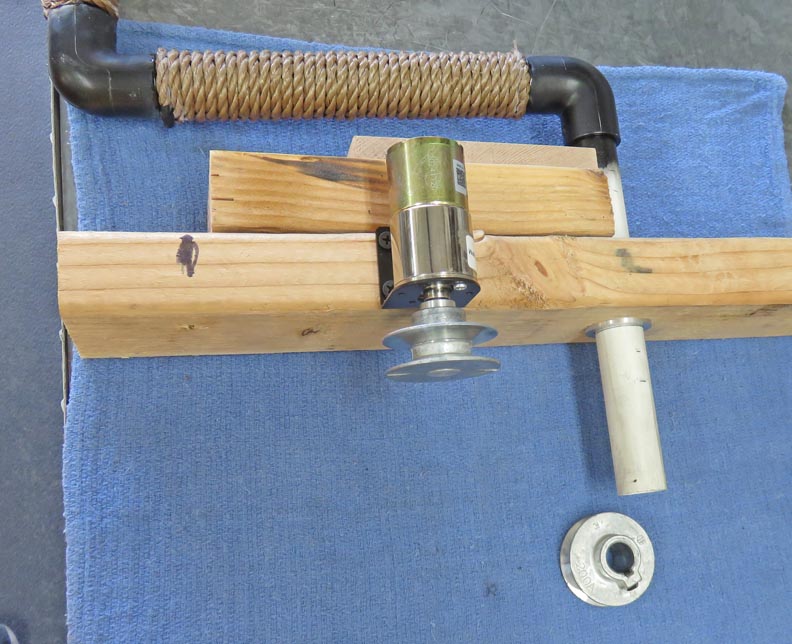

Here is the pulley assembly installed. I have a small amount of

adjustment on the motor shaft if I need it.

|

|

Here is a view from the other side. Now it's time to install the other

adapter into the PVC pipe and then cut the pipe to length.

|

|

I did some measuring and now I'm ready to cut the pipe to length. And

I'll have to relocate the motor slightly because the V belt is a little

too long for its current location.

|

|

Here I'm drilling a clearance hole through the PVC pipe which will put a

dimple into my adapter. This dimple will give me the location for some

threads that I'll be putting in.

|

|

A close-up of the hole and adapter. The smaller end of the adapter is

1/2" (right side) which is for the pulley.

|

|

Here is what the pulley assembly looks like. I made the ring at the top

to act as a kind of bushing that will go between the wood and the

pulley. This should provide a smoother operation this way.

|

|

|

Here you can see the thin bushing installed (arrow). I

thought this would help keep things in alignment so it would work

better. Also notice I've moved the motor over about one inch. If you

look close you can see two of the old mounting holes next to it. At this

point I'm done with the motor and pulleys, however, I noticed something

that could be improved on.

|

|

This is the end of the hand crank and the arrow is pointing to some

electrical tape covering the end. Well I thought I could make this look

a little better so I'm going to make something here.

|

|

|

1

2

3 |